Today we are going to start a very important topic here with the help of this post i.e. metal cutting tools: definition and classification.

So, let us first understand here the basics of metal cutting tool

Metal cutting tool: Definition

Metal cutting tool is basically defined as a device

used in metal cutting processes on machine tools for removing the layers of

materials from the workpiece or blank in order to secure the product of

specified size and shape with specified surface finish and accuracy.

Now we will see here the classification of metal

cutting tools

Classification of metal cutting tools

The metal cutting tools are classified on the basis of

number of cutting edges as mentioned below.

- Single point cutting tools

- Multi point cutting tools

- Forms tools

Single point cutting tools

A single point cutting tool will have an effective

cutting edge and it will remove the excess materials from the workpiece along

the cutting edge.

Single point cutting tools will be usually used on lathes, shapers, planers, etc.

Single point cutting tools are classified as mentioned below

- Forged tool

- Mechanically fastened tipped tool

- Brazed tipped tool

- Solid tool

- Tool bit inserted in the tool holder

- Right hand tool

- Left hand tool

- Round nose tool

Forged tool

Forged tools are manufactured from high speed steel or

high carbon steel. The required shape of the tool is given by forging the end

of a solid tool shank and further the cutting edges will be grounded to shape

to provide the required tool angles.

Following figure displayed here indicates the forged

tool.

Mechanically fastened tipped tool

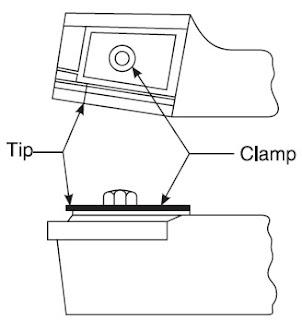

To ensure rigidity, tips are sometimes clamped at the

end of a tool shank by means of a clamp and bolt as displayed here in following

figure.

Brazed tipped tool

In brazed tipped type cutting tool, the cutting edge

will be in the form a small tip made up of stellite and cemented carbide tool

materials, which will be welded to the end of a carbon steel shank by brazing

operation.

Brazed tipped tool is displayed here in following

figure.

Solid tool

Solid tools are made up of high carbon steel, forged

and ground to the required shape. They are directly mounted on the tool post of

a lathe.

A lathe tool post is used to hold the metal cutting

tool.

Tool bit inserted in the tool holder

In case of tool bit inserted in the tool holder, metal

cutting tool will be inserted in a forged carbon steel tool holder and will be

clamped in a position by bolt or screw as displayed here in following figure.

There are various advantages of tool bit over solid

tool such as tool bit will be cheaper as compared to solid tool, regrinding of

tool will be quite easy.

A tool bit will be easily withdrawn and replaced in

position without disturbing the setting.

Right-hand tool and left-hand tool

A metal cutting tool will be said to be a right-hand

tool or left-hand tool, if its cutting edge is on the right-hand side or left-hand

side respectively when viewing the tool from the point end.

Multi point cutting tools

A multi-point cutting tool will have two or more than

two cutting edges. For example, metal cutting tools used in the operation of

drilling, milling and broaching will be considered as multi-point cutting

tools.

In multi-point cutting tools, all the cutting edges

may either operate one by one or engage simultaneously.

Each cutting edge of a multi-point cutting tool will

be considered as a separate single point cutting tool with almost all the

features of single point cutting tool.

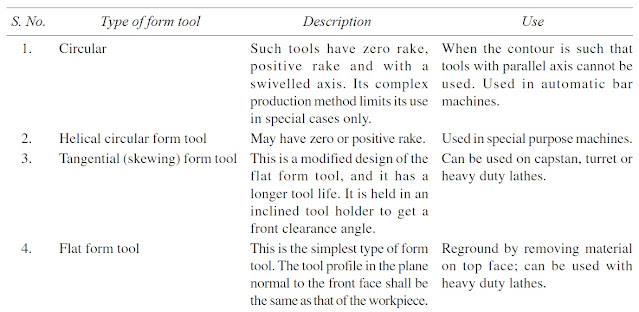

Form tools

A form tool is basically a metal cutting tool which is

shaped in such a way that it imparts a prespecified profile to the workpiece.

Form tools are usually ground on cutting tool elements

as a replica of the work profile. These tools are used to shape short jobs for

turret lathes.

Classification of form tools are displayed here in following table

Therefore, we have seen here the basics of metal

cutting tool i.e. definition of metal cutting tool and also the classification

of metal cutting tools with the help of this post.

Now, we will be interested further to understand a

very important concept in manufacturing process i.e. nomenclature of single point cutting tool with the help of our next post.

Do you have any suggestions? Please write in

comment box and also drop your email id in the given mail box which is given at

right hand side of page for further and continuous update from www.hkdivedi.com.

Reference:

Production Engineering, By K C Jain and A. K. Chitale

Image courtesy: Google

Also read

Positive

and negative effects of friction

Some

guidelines for solving frictional problems

Concept

of rolling resistance or rolling friction

Wedge friction and concept of self- locking

No comments:

Post a Comment