We were discussing Plumbing tools and their use with pictures and Pipe and Plumbing fittings. Let us now understand the with the help of this post.

Connections between pipes which are to be used under pressure are made with screwed couplings, screwed unions, flanges and chalked joints in socket and spigot joints.

Flexible and expansion joints are used where movements of the pipes and of the buildings are to be considered.

Types of Pipe Joints

The following three types of pipe joints are used in plumbing

1. Bell and spigot joints

2. Flanged joint

3. Threaded joint

Bell and spigot joints

The straight spigot end of the one section is inserted into the flared out end of the adjoining section as displayed in the following figure. These joints are used in a cast iron pipe, either water pipe or drainage pipe. For this type of joints, a space at least 15 cm around the pipes and a length of about one meter should be made available for sealing.

Sacramento state beautifully explained clear definition of Bell and spigot joints as mentioned below.

A form of joint used on pipes that have an enlarged diameter or bell at 1 end and a spigot at the other that fits into and is laid in the bell. The joint is then made tight by lead, cement, rubber O-ring, or other jointing compounds or materials.

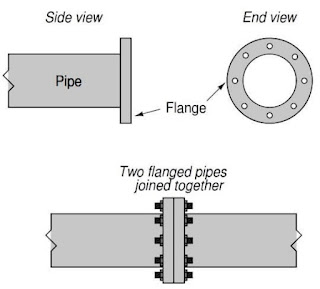

Flanged joints

There are two types of flanged joints as mentioned below

1. Ring gasket flange joint

2. Full face gasket flange joint

These joints are easy for removing and re-fixing by bolting and gaskets to form a watertight joint. Also flanged joints are preferred to lay the lengthy pipe lines.

Flanges can be joined by means of bolt and nuts. Holes must be created using drilling tools in both the flanges in similar PCD with the diameter equal to the external diameter of the bolt. Both flanges can be lapped and bolted joints can be obtained as shown in the figure.

Threaded joints

The threaded joints are shown in the following figure. It can be obtained by connecting two pipes having external threads at both ends using coupling. Grease should be applied to the external threads of the pipes for easy connections. Lamp wick can be wrapped outside the threads to obtain tight joints. Adequate space must be provided to facilitate and make these joints. Red lead, white lead mixed with oil or grease can also be used for threaded joints.

Credit- https://www.istockphoto.com/photos/threaded-pipe

Reference

Engineering Practices by Mr. S. SUYAMBAZHAHAN

This comment has been removed by a blog administrator.

ReplyDelete