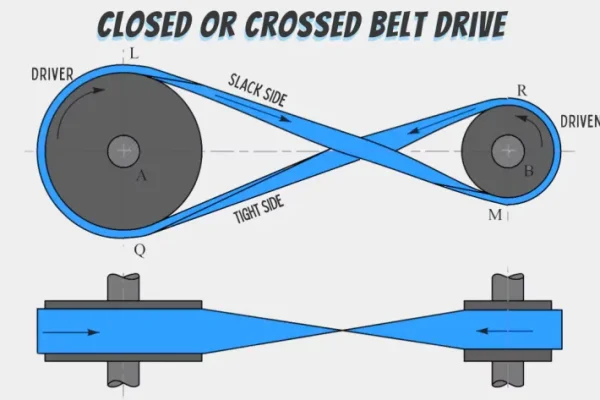

Types of Belt Drives and Their Applications – Engineering Made Easy

In the field of mechanical engineering and maintenance, belt drives represent one of the most widely used and versatile methods for transmitting power between rotating shafts. These flexible power transmission systems have been fundamental to industrial machinery since the early days of mechanization and continue to play a crucial role in modern manufacturing, transportation, and…