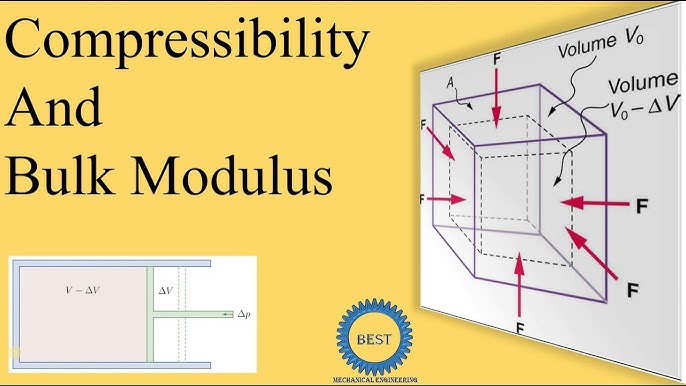

In the study of fluid mechanics, understanding the compressibility of fluids and the associated bulk modulus is fundamental to analyzing how substances respond to pressure changes. These properties are crucial for engineers working with hydraulic systems, pipeline design, water hammer analysis, and numerous other applications where fluid behavior under pressure is critical.

While gases are inherently compressible and their behavior is well described by the ideal gas law, liquids are often considered incompressible for many practical applications. However, under extreme conditions or in precision engineering applications, even liquids exhibit measurable compressibility that must be accounted for in design calculations. The bulk modulus provides a quantitative measure of a substance’s resistance to uniform compression and is directly related to its compressibility.

Introduction to Compressibility

Compressibility is a fundamental property of all substances that measures the relative volume change in response to a pressure change. It is a dimensionless quantity that provides insight into how easily a material can be compressed under external pressure. In fluid mechanics, compressibility plays a critical role in determining the speed of sound in a medium, the behavior of fluids under rapid pressure changes, and the accuracy of various hydraulic systems.

Mathematically, compressibility is defined as:

Where:

- β is the compressibility of the substance

- V is the volume of the substance

- P is the pressure acting on the substance

- dV/dP is the derivative of volume with respect to pressure

The negative sign in the definition ensures that compressibility is a positive quantity, since an increase in pressure typically results in a decrease in volume.

Compressibility is particularly important in fluid mechanics because it determines whether a fluid can be treated as incompressible for analytical purposes. In many engineering applications, liquids are assumed to be incompressible, but this assumption has limitations that must be understood and accounted for when necessary.

Bulk Modulus (K)

The bulk modulus is the inverse of compressibility and represents a substance’s resistance to uniform compression. It is a measure of how much pressure is required to cause a given relative decrease in volume. The bulk modulus is particularly important in fluid mechanics for understanding phenomena such as water hammer effects, the speed of sound in fluids, and the behavior of hydraulic systems under pressure.

Definition

The bulk modulus is defined as:

Where:

- K is the bulk modulus of the substance

- V is the volume of the substance

- P is the pressure acting on the substance

- dP/dV is the derivative of pressure with respect to volume

The negative sign indicates that an increase in pressure results in a decrease in volume. Since both dP and dV have the same sign (both positive or both negative), the bulk modulus is always a positive quantity.

Mathematical Relationship with Compressibility

The relationship between bulk modulus and compressibility is straightforward:

This inverse relationship means that substances with high bulk moduli have low compressibility, and vice versa. A large bulk modulus indicates that the substance is nearly incompressible, while a small bulk modulus indicates that the substance is highly compressible.

Physical Interpretation

The bulk modulus provides several important insights into material behavior:

- Stiffness Measure: It represents the “stiffness” of a material with respect to volume changes under pressure

- Energy Storage: It indicates how much energy can be stored in a material through compression

- Wave Propagation: It directly affects the speed of sound in the material

- System Response: It determines how quickly pressure changes propagate through a fluid

Units and Typical Values

The bulk modulus has units of pressure (force per unit area). In SI units, it is measured in Pascals (Pa) or more commonly in gigapascals (GPa). In imperial units, it may be expressed in pounds per square inch (psi) or kilopounds per square inch (ksi).

Typical values for common substances include:

- Water: Approximately 2.2 GPa (22,000 atm)

- Oil: Approximately 1.5 GPa (15,000 atm)

- Air (at atmospheric pressure): Approximately 101 kPa (1 atm)

- Steel: Approximately 160 GPa (1,600,000 atm)

These values illustrate the enormous difference in compressibility between liquids and gases. Water, which is often considered incompressible, still has a finite compressibility that must be considered in precision applications.

Compressibility (β)

Compressibility is the reciprocal of the bulk modulus and provides a direct measure of how much a substance’s volume changes under pressure. While bulk modulus indicates resistance to compression, compressibility indicates the ease of compression.

Definition

As previously defined:

The compressibility can also be expressed in terms of density changes:

Where ρ is the density of the substance.

Units and Interpretation

Compressibility has units of inverse pressure (1/Pa in SI units). A higher compressibility value indicates that the substance is more easily compressed, while a lower value indicates greater resistance to compression.

For practical interpretation:

- High Compressibility: Large volume change for small pressure change

- Low Compressibility: Small volume change for large pressure change

Temperature Dependence

Both bulk modulus and compressibility are functions of temperature:

- Liquids: Bulk modulus generally decreases with increasing temperature

- Gases: Compressibility is strongly dependent on both temperature and pressure

- Solids: Bulk modulus typically decreases with increasing temperature

Applications in Fluid Mechanics

Understanding compressibility and bulk modulus is crucial for numerous applications in fluid mechanics. These properties affect the behavior of fluids in various engineering systems and must be properly accounted for in design and analysis.

Water Hammer Effects

Water hammer is a pressure surge that occurs when flowing liquid is suddenly stopped, such as when a valve closes rapidly. The compressibility of the liquid and the bulk modulus of the pipe material both affect the magnitude and duration of the pressure surge.

The pressure rise due to water hammer can be estimated using:

Where:

- ΔP is the pressure rise

- ρ is the fluid density

- c is the speed of sound in the fluid

- ΔV is the change in fluid velocity

The speed of sound in a fluid is related to the bulk modulus:

This relationship shows why water hammer effects are more severe in less compressible fluids – they have higher bulk moduli and therefore higher speeds of sound, leading to more rapid pressure wave propagation.

Hydraulic System Design

In hydraulic systems, the compressibility of the working fluid affects system response time and stability:

- Response Time: More compressible fluids result in slower system response due to energy storage in compression

- Stability: Compressibility can affect system stability and control characteristics

- Efficiency: Energy stored in fluid compression must be accounted for in efficiency calculations

Pipeline Transients

The analysis of transient flow in pipelines requires consideration of fluid compressibility:

- Pressure Wave Propagation: Bulk modulus determines the speed of pressure waves through the pipeline

- Surge Analysis: Compressibility affects the magnitude and duration of pressure surges

- Valve Closure: Rapid valve closure can cause significant pressure transients in compressible fluids

Cavitation Analysis

Compressibility affects the onset and behavior of cavitation in flowing liquids:

- Nucleation: Compressibility affects the formation and growth of vapor bubbles

- Collapse Dynamics: Bulk modulus influences the violence of bubble collapse

- Damage Potential: More compressible fluids may exhibit different cavitation damage characteristics

Speed of Sound in Fluids

One of the most important applications of bulk modulus is in determining the speed of sound in a fluid medium. The speed of sound is a fundamental property that affects numerous aspects of fluid behavior and system performance.

Mathematical Relationship

The speed of sound in a fluid is given by:

Where:

- c is the speed of sound in the fluid

- K is the bulk modulus of the fluid

- ρ is the density of the fluid

This relationship shows that the speed of sound increases with increasing bulk modulus and decreases with increasing density.

Typical Values

Speed of sound values for common fluids include:

- Water (20°C): Approximately 1,480 m/s (4,860 ft/s)

- Oil (typical): Approximately 1,200-1,400 m/s (3,900-4,600 ft/s)

- Air (20°C, 1 atm): Approximately 343 m/s (1,125 ft/s)

These values illustrate why pressure waves propagate much more quickly in liquids than in gases, due to the much higher bulk modulus of liquids.

Engineering Implications

The speed of sound has important implications in engineering applications:

- System Response: Determines how quickly pressure changes propagate through a system

- Control Systems: Affects the bandwidth and response characteristics of hydraulic controls

- Measurement Systems: Influences the frequency response of pressure measurement devices

- Safety Systems: Critical for designing pressure relief and surge protection systems

Measurement Techniques

Accurate measurement of bulk modulus and compressibility is essential for engineering applications. Various techniques have been developed for these measurements, each with its own advantages and limitations.

Static Methods

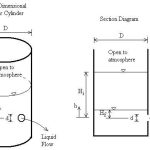

Static methods involve applying a known pressure change and measuring the resulting volume change:

- Hydrostatic Compression: Applying uniform pressure and measuring volume change

- Piston Cylinder Methods: Using precision pistons to apply controlled pressure

- Bomb Calorimetry: For high-pressure measurements

Dynamic Methods

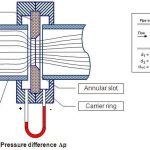

Dynamic methods use pressure wave propagation to determine bulk modulus:

- Sound Speed Measurements: Measuring speed of sound and calculating bulk modulus

- Ultrasonic Methods: Using high-frequency pressure waves

- Resonance Techniques: Measuring natural frequencies of fluid-filled systems

Specialized Techniques

Specialized techniques for specific applications include:

- High-Pressure Methods: For extreme pressure conditions

- Temperature-Controlled Measurements: For studying temperature effects

- Mixture Analysis: For determining properties of fluid mixtures

Sample Problems and Calculations

Let’s work through some sample problems to illustrate the application of compressibility and bulk modulus concepts in practical engineering situations.

Problem 1: Bulk Modulus Calculation

A liquid has a volume of 0.5 m³ at a pressure of 100 kPa. When the pressure is increased to 2,100 kPa, the volume decreases to 0.495 m³. Calculate the bulk modulus of the liquid.

Given:

- V₁ = 0.5 m³

- P₁ = 100 kPa

- V₂ = 0.495 m³

- P₂ = 2,100 kPa

Solution:

First, calculate the changes:

Using the bulk modulus formula:

Using the average volume:

Therefore, the bulk modulus of the liquid is approximately 199 MPa.

Problem 2: Compressibility and Volume Change

The compressibility of a certain oil is 7 × 10⁻¹⁰ Pa⁻¹. If 2 m³ of this oil is subjected to a pressure increase of 10 MPa, what is the change in volume?

Given:

- β = 7 × 10⁻¹⁰ Pa⁻¹

- V = 2 m³

- ΔP = 10 MPa = 10⁷ Pa

Solution:

Using the compressibility formula:

For finite changes:

Solving for ΔV:

The negative sign indicates a decrease in volume. Therefore, the volume decreases by 0.014 m³ or 14 liters.

Problem 3: Speed of Sound Calculation

Calculate the speed of sound in water given that its bulk modulus is 2.2 GPa and its density is 1,000 kg/m³.

Given:

- K = 2.2 GPa = 2.2 × 10⁹ Pa

- ρ = 1,000 kg/m³

Solution:

Using the speed of sound formula:

This result is consistent with the known speed of sound in water at room temperature.

Factors Affecting Bulk Modulus and Compressibility

Both bulk modulus and compressibility are influenced by various factors that must be considered in engineering applications.

Temperature Effects

Temperature has significant effects on both properties:

- Liquids: Bulk modulus generally decreases with increasing temperature

- Gases: Compressibility increases with increasing temperature at constant pressure

- Solids: Bulk modulus typically decreases with increasing temperature

Pressure Effects

Pressure also affects these properties:

- Liquids: Bulk modulus generally increases with pressure

- Gases: Compressibility decreases with increasing pressure

- Solids: Bulk modulus increases with pressure

Composition Effects

The composition of fluid mixtures affects their compressibility properties:

- Mixture Rules: Properties of mixtures can be estimated using mixing rules

- Dissolved Gases: Even small amounts of dissolved gas can significantly affect liquid compressibility

- Contaminants: Impurities can alter bulk modulus and compressibility

Advanced Considerations

For specialized applications, more advanced considerations of compressibility and bulk modulus may be necessary.

Dynamic Bulk Modulus

Under rapid pressure changes, the effective bulk modulus may differ from static values:

- Frequency Dependence: Bulk modulus may vary with the frequency of pressure oscillations

- Viscous Effects: Viscosity can affect the effective bulk modulus in dynamic situations

- Relaxation Processes: Molecular relaxation can influence dynamic compressibility

Nonlinear Effects

At extreme pressures, the relationship between pressure and volume may become nonlinear:

- Equations of State: More complex equations may be needed for accurate predictions

- Tait Equation: Used for liquids under high pressure

- Murnaghan Equation: Used for solids under high pressure

Anisotropic Materials

Some materials have directionally dependent compressibility:

- Crystalline Solids: May have different bulk moduli in different crystallographic directions

- Composite Materials: May exhibit anisotropic behavior

- Biological Tissues: Often show anisotropic compressibility

Conclusion

Compressibility and bulk modulus are fundamental properties in fluid mechanics that govern how substances respond to pressure changes. While these properties are often overlooked in basic engineering analyses, they play crucial roles in determining the behavior of fluids in numerous practical applications.

The inverse relationship between compressibility and bulk modulus (K = 1/β) provides two complementary ways to understand and quantify a material’s response to pressure. Bulk modulus indicates resistance to compression, while compressibility indicates ease of compression. Both perspectives are valuable in different contexts.

The applications of these properties in fluid mechanics are extensive and important. From water hammer analysis to hydraulic system design to pipeline transient analysis, understanding compressibility and bulk modulus is essential for predicting and controlling fluid behavior. The relationship between bulk modulus and the speed of sound is particularly important for understanding how pressure changes propagate through fluid systems.

The sample problems demonstrate the practical calculations involved in determining these properties and their effects. Even small changes in volume due to pressure changes can have significant impacts in engineering systems, particularly in precision applications or systems operating at high pressures.

Temperature, pressure, and compositional effects show that bulk modulus and compressibility are not constant properties but vary with conditions. Engineers must consider these variations when designing systems that operate over wide ranges of conditions.

Advanced considerations such as dynamic effects, nonlinear behavior, and anisotropy become important in specialized applications. These factors may require more sophisticated analysis techniques and property models.

For students and practitioners of fluid mechanics, a solid understanding of compressibility and bulk modulus is essential for proper analysis and design of fluid systems. While many introductory courses treat liquids as perfectly incompressible, real-world engineering often requires consideration of finite compressibility effects.

The measurement techniques available for determining these properties continue to improve, providing more accurate data for engineering applications. Both static and dynamic methods have their place depending on the specific requirements of the application.

As engineering systems continue to operate at higher pressures, faster response times, and more extreme conditions, the importance of understanding compressibility and bulk modulus will only increase. These fundamental properties will remain essential tools for engineers working with fluid systems in diverse applications from aerospace to biomedical to energy systems.

In conclusion, compressibility and bulk modulus represent fundamental material properties that bridge the gap between basic fluid mechanics principles and real-world engineering applications. Mastery of these concepts enables engineers to design more reliable, efficient, and safe fluid systems across a wide range of industries and applications.