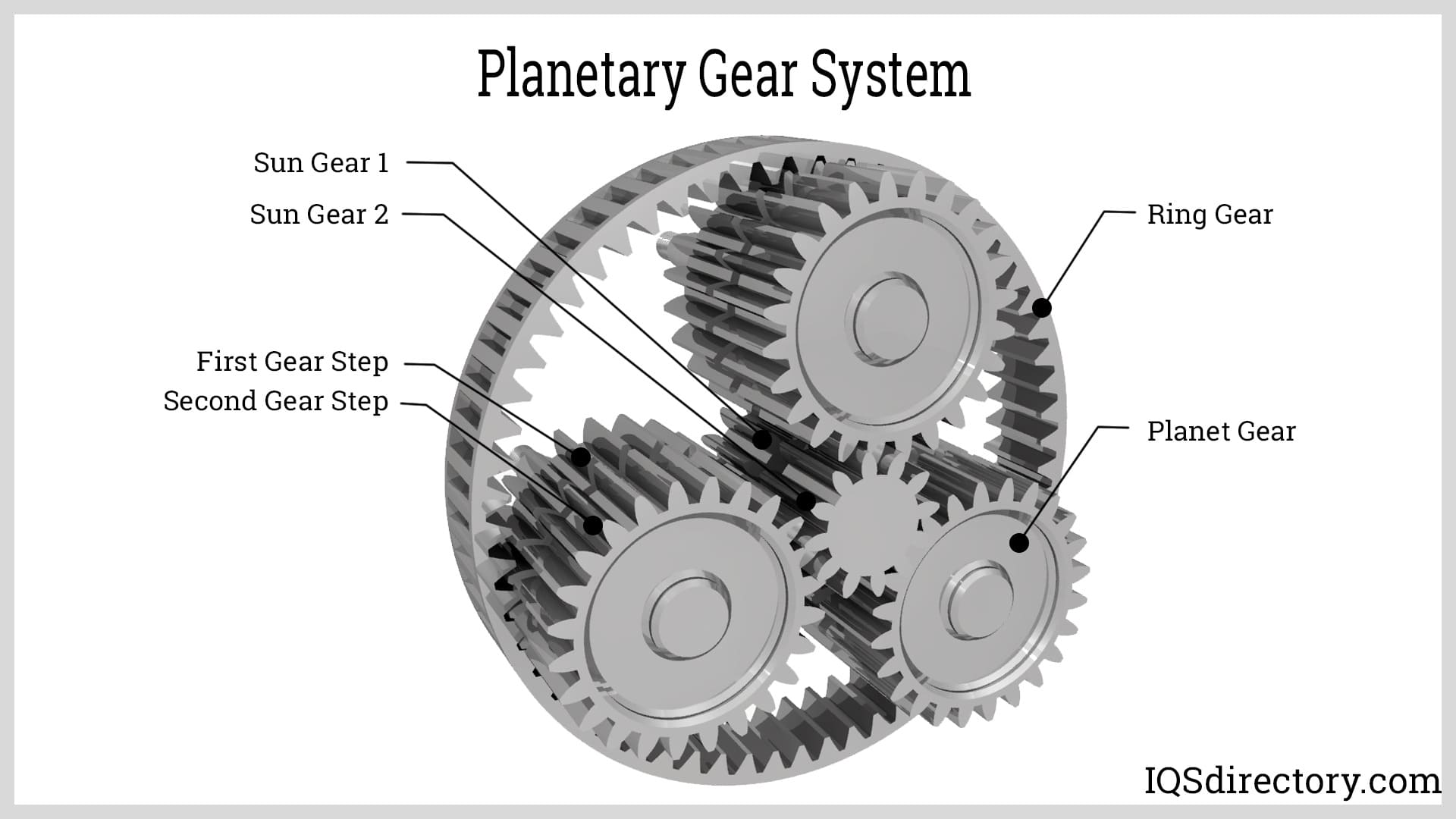

In the field of mechanical engineering and maintenance, planetary gear systems represent one of the most sophisticated and versatile mechanisms for power transmission. Also known as epicyclic gear trains, these complex assemblies offer unique advantages in terms of power density, compactness, and versatility that make them indispensable in numerous modern applications.

Planetary gears are characterized by their distinctive configuration, where multiple planet gears revolve around a central sun gear while simultaneously rotating on their own axes. This arrangement, housed within an outer ring gear, creates multiple simultaneous gear meshes that distribute loads effectively and enable various speed and torque relationships between input and output shafts.

Introduction to Planetary Gears

Planetary gear systems, also referred to as epicyclic gear trains, are mechanical assemblies that consist of multiple gears arranged in a specific configuration to achieve complex motion and power transmission relationships. The name “planetary” derives from the resemblance of the gear arrangement to the solar system, with the central sun gear representing the sun, the orbiting planet gears representing planets, and the outer ring gear representing the celestial sphere.

The fundamental concept of planetary gearing has been known since ancient times, with early examples found in the Antikythera mechanism, a Greek astronomical device dating to the 2nd century BCE. However, modern planetary gear systems have evolved into highly engineered components that provide exceptional performance characteristics in contemporary mechanical systems.

The unique arrangement of planetary gears offers several distinct advantages:

- Compact Design: High power density in a relatively small envelope

- Load Distribution: Multiple planet gears share the transmitted load

- Versatility: Multiple speed and torque relationships possible

- Coaxial Arrangement: Input and output shafts can be aligned

- Smooth Operation: Multiple simultaneous meshes reduce vibration and noise

These characteristics make planetary gears ideal for applications where space is limited, high torque density is required, or complex speed relationships are needed.

Basic Components

A planetary gear system consists of four primary components that work together to achieve the desired motion and power transmission characteristics. Understanding these components is essential for comprehending how planetary gears function and how they can be applied in various mechanical systems.

Sun Gear

The sun gear is the central gear in the planetary gear system and is typically the smallest gear in the assembly. It is positioned at the center of the system and meshes directly with all the planet gears.

Key characteristics of the sun gear include:

- Central Position: Located at the geometric center of the planetary gear system

- Direct Meshing: Engages directly with all planet gears simultaneously

- Rotation Capability: Can rotate independently or be fixed depending on the application

- Size Relationship: Typically smaller than both planet gears and ring gear

- Power Transmission: Primary pathway for power input or output in many configurations

The sun gear’s rotation direction and speed are critical factors in determining the overall gear ratio and motion characteristics of the planetary system.

Planet Gears

Planet gears are multiple gears that orbit around the sun gear while simultaneously rotating on their own axes. The number of planet gears in a system can vary, with typical configurations using 3, 4, 5, or 6 planet gears depending on the design requirements and load distribution needs.

Key characteristics of planet gears include:

- Multiple Units: Usually 3-6 identical gears arranged symmetrically around the sun gear

- Dual Motion: Revolve around the sun gear while rotating on their own axes

- Load Sharing: Distribute transmitted loads evenly among all planet gears

- Mesh Relationships: Engage simultaneously with both sun gear and ring gear

- Size Consistency: All planet gears in a system are typically identical in size and tooth count

The planet gears are the workhorses of the planetary system, transferring power between the sun gear and ring gear while providing the load distribution that gives planetary gears their strength advantage.

Planet Carrier

The planet carrier is a structural component that holds the planet gears in their proper positions and allows them to rotate while maintaining their orbital relationship with the sun gear. The carrier typically consists of arms or spokes that connect to the planet gears at specific mounting points.

Key characteristics of the planet carrier include:

- Structural Support: Provides mounting points and maintains planet gear positioning

- Motion Capability: Can rotate as an assembly with the planet gears

- Load Transfer: Transmits forces between planet gears and output shaft

- Design Variations: May be solid, spoked, or webbed depending on application requirements

- Attachment Points: Connects to planet gears through pins, bearings, or integral shafts

The planet carrier serves as a critical interface between the rotating planet gears and the stationary or rotating output shaft, making it one of the most complex components in terms of stress analysis and fatigue life.

Ring Gear

The ring gear, also known as the annulus or internal gear, is the outer gear that surrounds the entire planetary gear assembly. It has internal teeth that mesh with the planet gears and provides the outer boundary of the gear system.

Key characteristics of the ring gear include:

- Internal Teeth: Features teeth on the inner circumference that mesh with planet gears

- Outer Boundary: Defines the maximum diameter of the planetary gear system

- Mounting Structure: Often integrated with the housing or gearbox casing

- Size Relationship: Typically the largest gear in the assembly

- Fixed or Rotating: Can be fixed or allowed to rotate depending on application

The ring gear’s internal tooth design requires special manufacturing considerations and presents unique challenges in terms of stress distribution and lubrication compared to external gears.

Working Principle

Understanding the working principle of planetary gears requires grasping the complex motion relationships between the various components. The simultaneous rotation and revolution of the planet gears create unique kinematic possibilities that distinguish planetary gear systems from simpler gear arrangements.

Motion Relationships

The fundamental motion relationship in planetary gears involves the interaction between the three main elements: sun gear, planet gears, and ring gear. Each of these elements can serve as input, output, or reaction member, creating different operational modes.

The basic motion relationships include:

- Revolution: Planet gears orbit around the sun gear at a specific angular velocity

- Rotation: Planet gears spin on their own axes as they revolve

- Superposition: The total motion of planet gears is the sum of revolution and rotation

- Differential Motion: Relative motions between components create complex speed relationships

These motion relationships are governed by the geometric constraints imposed by the gear meshing and the requirement that all gears maintain proper tooth engagement throughout their motion.

Kinematic Analysis

The kinematic analysis of planetary gears involves understanding the relationship between the angular velocities of the sun gear (ωₛ), ring gear (ωᵣ), and planet carrier (ω_c). This relationship is expressed through the fundamental planetary gear equation:

Where:

- ωₛ = Angular velocity of sun gear

- ωᵣ = Angular velocity of ring gear

- ω_c = Angular velocity of planet carrier

- Nₛ = Number of teeth on sun gear

- Nᵣ = Number of teeth on ring gear

This equation forms the basis for analyzing all possible operating conditions of planetary gear systems.

Speed Ratios

The speed ratios in planetary gears depend on which component is fixed and which serve as input and output. For example, when the ring gear is fixed:

When the sun gear is fixed:

These relationships demonstrate the versatility of planetary gear systems in achieving various speed and torque combinations.

Advantages

Planetary gear systems offer numerous advantages that make them attractive for many engineering applications. These benefits stem from the unique geometric arrangement and multiple simultaneous gear meshes that characterize these systems.

High Power Density

One of the most significant advantages of planetary gears is their exceptional power density, which refers to the amount of power that can be transmitted relative to the system’s size and weight.

- Compact Envelope: Planetary gears achieve high torque transmission in a relatively small space

- Weight Efficiency: Higher power-to-weight ratios compared to equivalent parallel shaft gear systems

- Space Utilization: Efficient use of radial space through concentric arrangement

- Volume Optimization: Minimum volume for maximum power transmission capability

This high power density makes planetary gears ideal for applications where space and weight are critical constraints, such as in automotive transmissions and aerospace systems.

Load Distribution

The multiple planet gears in planetary systems provide excellent load distribution characteristics that enhance durability and performance.

- Multiple Mesh Points: Several simultaneous gear meshes distribute loads evenly

- Reduced Tooth Loading: Individual tooth loads are reduced compared to single gear pairs

- Improved Fatigue Life: Even load distribution extends component service life

- Enhanced Reliability: Reduced likelihood of catastrophic failure due to overload

Coaxial Input/Output

Planetary gears can provide coaxial input and output shafts, which is a significant advantage in many applications.

- Alignment Simplicity: Input and output shafts can be perfectly aligned

- Reduced Complexity: Eliminates need for additional alignment components

- Space Efficiency: Straight-line power transmission path

- Installation Ease: Simplifies system integration and maintenance

Versatility

The ability to achieve multiple speed and torque relationships makes planetary gears extremely versatile.

- Multiple Ratios: Different configurations provide various speed ratios

- Reversible Operation: Same system can provide speed increase or reduction

- Flexible Configurations: Different components can serve as input, output, or reaction members

- Customizable Ratios: Gear tooth counts can be selected to achieve specific ratios

Disadvantages

Despite their many advantages, planetary gear systems also have several disadvantages that must be considered during design and application selection.

Complexity

The intricate arrangement of multiple components in planetary gears creates inherent complexity in design, manufacturing, and maintenance.

- Design Complexity: Requires sophisticated analysis and optimization techniques

- Manufacturing Challenges: Complex geometry requires specialized machining processes

- Assembly Difficulty: Precise alignment and assembly of multiple components

- Maintenance Complexity: Difficult access for inspection and servicing

Cost

Planetary gear systems typically have higher initial costs compared to simpler gear arrangements.

- Manufacturing Costs: Complex geometry increases production costs

- Tooling Expenses: Specialized tooling required for internal gear cutting

- Assembly Costs: Skilled labor and precision equipment needed for assembly

- Quality Control: Extensive inspection and testing requirements

Lubrication Challenges

The enclosed nature of planetary gear systems presents unique lubrication challenges.

- Access Limitations: Difficulty in reaching all mesh points for lubrication

- Circulation Issues: Complex flow paths within the gear assembly

- Temperature Management: Heat dissipation challenges in enclosed spaces

- Lubricant Degradation: Contamination and breakdown in enclosed environments

Manufacturing Tolerances

Achieving the required precision for proper operation demands tight manufacturing tolerances.

- Center Distance Tolerances: Critical for proper gear meshing and load distribution

- Tooth Profile Accuracy: Essential for smooth operation and load sharing

- Assembly Clearances: Must be controlled to prevent binding or excessive play

- Material Consistency: Uniform properties required for predictable performance

Applications

Planetary gear systems find applications across numerous industries due to their unique combination of characteristics and performance benefits.

Automotive Industry

The automotive industry is one of the largest users of planetary gear systems.

- Automatic Transmissions: Primary component in multi-speed automatic transmissions

- Differentials: Limited-slip differentials using planetary gear principles

- Hybrid Systems: Power split devices in hybrid vehicle drivetrains

- Transfer Cases: Four-wheel drive systems utilizing planetary arrangements

Aerospace Industry

Aerospace applications demand the high power density and reliability that planetary gears provide.

- Aircraft Engines: Reduction gears in turboprop and turbofan engines

- Helicopter Transmissions: Main rotor gearboxes using planetary stages

- Actuation Systems: Control surface actuators with integrated planetary reducers

- Auxiliary Power Units: Compact power transmission in APUs

Industrial Machinery

Industrial applications benefit from the versatility and load capacity of planetary gears.

- Wind Turbines: Main gearboxes in wind turbine drivetrains

- Construction Equipment: Final drives in excavators and bulldozers

- Machine Tools: Precision indexing mechanisms and rotary tables

- Conveyor Systems: Drive units for heavy-duty conveyor applications

Consumer Products

Consumer applications leverage the compact size and efficiency of planetary gears.

- Electric Tools: Cordless drills and screwdrivers with planetary gear motors

- Bicycles: Internal gear hubs using planetary gear systems

- Cameras: Auto-focus mechanisms in photographic equipment

- Robotic Systems: Joint actuators in robotic arms and manipulators

Maintenance Considerations

Proper maintenance of planetary gear systems is critical for ensuring long service life and reliable operation.

Inspection Procedures

Regular inspection procedures help identify potential issues before they lead to failure.

- Visual Inspection: Check for signs of wear, damage, or contamination

- Noise Monitoring: Listen for unusual sounds that may indicate problems

- Vibration Analysis: Monitor vibration patterns for early detection of issues

- Temperature Monitoring: Track operating temperatures for abnormal heat generation

Lubrication Management

Proper lubrication is essential for planetary gear system longevity.

- Lubricant Selection: Choose appropriate lubricants based on operating conditions

- Replacement Intervals: Follow manufacturer recommendations for lubricant changes

- Contamination Control: Prevent ingress of dirt, moisture, and other contaminants

- System Monitoring: Check lubricant condition through analysis and testing

Common Failure Modes

Understanding common failure modes helps in preventive maintenance planning.

- Tooth Wear: Progressive removal of material from gear teeth surfaces

- Fatigue Cracking: Crack initiation and propagation in gear teeth or carriers

- Bearing Failure: Deterioration of planet gear bearings due to load or contamination

- Lubrication Failure: Inadequate lubrication leading to scuffing or seizing

Design Considerations

Successful planetary gear design requires careful attention to numerous factors that affect performance and reliability.

Load Distribution

Ensuring even load distribution is critical for optimal performance and longevity.

- Planet Count: Select appropriate number of planet gears for load sharing

- Tolerance Control: Maintain tight tolerances to ensure even load distribution

- Flexibility Considerations: Account for manufacturing and assembly variations

- Stress Analysis: Perform detailed stress analysis for critical components

Materials Selection

Material selection significantly affects gear performance and service life.

- Gear Materials: Select materials with appropriate strength and wear resistance

- Heat Treatment: Apply proper heat treatment for desired material properties

- Surface Finishing: Implement appropriate surface treatments for durability

- Compatibility: Ensure material compatibility for all contacting surfaces

Manufacturing Processes

Manufacturing processes must achieve the precision required for proper operation.

- Gear Cutting: Use appropriate methods for internal and external gear teeth

- Precision Machining: Maintain tight tolerances on critical dimensions

- Quality Control: Implement rigorous inspection procedures

- Assembly Techniques: Use proper methods for component assembly and alignment

Sample Problems and Calculations

Let’s work through some sample problems to illustrate planetary gear analysis and design considerations.

Problem 1: Basic Speed Ratio Calculation

A planetary gear system has the following specifications:

- Sun gear teeth (Nₛ) = 20

- Ring gear teeth (Nᵣ) = 60

- Number of planet gears = 4

- Sun gear is the input, ring gear is fixed, carrier is the output

Calculate the speed ratio and determine if it’s a speed reducer or increaser.

Solution:

Using the speed ratio formula for fixed ring gear:

Since the speed ratio is greater than 1, this configuration provides a 4:1 speed reduction. The carrier rotates at 1/4 the speed of the sun gear.

Problem 2: Torque Relationship

For the same planetary gear system as Problem 1, if the input torque on the sun gear is 100 Nm, calculate the output torque at the carrier, assuming 95% efficiency.

Solution:

Torque relationship is the inverse of speed relationship, modified by efficiency:

The output torque at the carrier is 380 Nm, demonstrating the torque multiplication capability of planetary gears.

Problem 3: Load Distribution Analysis

A planetary gear system with 5 planet gears transmits a total torque of 500 Nm. Calculate the torque carried by each planet gear and discuss the implications for design.

Solution:

If the load is evenly distributed among 5 planet gears:

This calculation shows that load distribution reduces the torque on individual components, but the design must ensure that this distribution remains even under all operating conditions. Manufacturing tolerances and assembly variations must be controlled to maintain this even load distribution.

Conclusion

Planetary gear systems represent one of the most sophisticated and versatile mechanisms in mechanical engineering, offering unique combinations of compactness, power density, and operational flexibility that make them indispensable in numerous modern applications. Their distinctive configuration, with multiple planet gears orbiting a central sun gear within an outer ring gear, creates complex motion relationships that enable various speed and torque combinations in a remarkably compact package.

The fundamental components of planetary gears—sun gear, planet gears, planet carrier, and ring gear—work in concert to create the unique characteristics that distinguish these systems from simpler gear arrangements. Understanding the roles and interactions of these components is essential for proper application and maintenance of planetary gear systems.

The working principle of planetary gears, based on the simultaneous revolution and rotation of planet gears, creates multiple simultaneous gear meshes that distribute loads effectively and enable the achievement of various speed ratios depending on which components serve as input, output, and reaction members. The kinematic relationships governing these systems provide the mathematical foundation for analyzing and designing planetary gear applications.

The advantages of planetary gears are compelling and numerous. Their high power density enables significant torque transmission in compact envelopes, making them ideal for applications where space and weight are critical constraints. The excellent load distribution among multiple planet gears enhances durability and reliability while reducing individual component stresses. The ability to achieve coaxial input and output shafts simplifies system integration, and the versatility in achieving various speed ratios makes these systems adaptable to numerous applications.

However, these advantages come with corresponding disadvantages that must be carefully considered. The complexity of planetary gear systems increases design, manufacturing, and maintenance challenges. Higher initial costs, sophisticated lubrication requirements, and tight manufacturing tolerances add to the overall expense and complexity of these systems. These factors must be weighed against the benefits when selecting power transmission solutions.

The widespread applications of planetary gears across industries—from automotive transmissions to aerospace propulsion systems, industrial machinery to consumer products—demonstrate their value and versatility. The ability to customize gear ratios, achieve high efficiency, and provide reliable operation in demanding environments has made planetary gears the preferred choice for many critical applications.

Maintenance considerations for planetary gears emphasize the importance of proper lubrication, regular inspection, and understanding of common failure modes. The enclosed nature of these systems requires special attention to lubrication management and contamination control to ensure long service life and reliable operation.

Design considerations highlight the critical importance of load distribution, material selection, and manufacturing precision in achieving optimal performance and longevity. The sample problems demonstrate the mathematical relationships that govern planetary gear operation and the practical implications for torque transmission and load sharing.

For students and practitioners of mechanical engineering and maintenance, understanding planetary gear systems provides valuable insights into advanced power transmission concepts and practical problem-solving approaches. The combination of theoretical analysis with practical application considerations prepares professionals to make informed decisions about gear system selection and application.

As technology continues to advance, planetary gear systems are likely to benefit from improvements in materials science, manufacturing precision, and design optimization techniques. These developments will likely enhance the already impressive capabilities of planetary gears while potentially reducing some of their current disadvantages.

In conclusion, planetary gear systems represent a mature yet evolving technology that continues to provide exceptional value in power transmission applications. Their unique combination of characteristics makes them irreplaceable in many critical applications, and their continued development promises even greater capabilities for future engineering challenges. Understanding these systems is essential for any professional working in mechanical design, power transmission, or maintenance of rotating machinery.