The Stirling cycle represents one of the most efficient and elegant thermodynamic cycles in the field of thermal engineering. Named after its inventor, Robert Stirling, a Scottish minister and engineer who patented the concept in 1816, this cycle has garnered significant attention for its theoretical capability to achieve the maximum possible thermal efficiency as defined by the Carnot efficiency. The Stirling cycle is a closed regenerative thermodynamic cycle that offers unique advantages in terms of efficiency, quiet operation, and fuel flexibility.

Unlike internal combustion engines that burn fuel directly within the working cylinder, Stirling engines operate on an external combustion principle, where heat is supplied from an external source to drive the cycle. This fundamental difference provides several benefits, including the ability to use virtually any heat source, reduced emissions, and the potential for very high efficiency when properly designed and implemented.

Introduction to the Stirling Cycle

The Stirling cycle is a thermodynamic cycle that describes the operation of a theoretical heat engine using external heat exchange with a regenerative heat exchanger. It consists of four distinct processes that form a closed loop, returning the working fluid to its initial state after completing one cycle. What makes the Stirling cycle particularly remarkable is its theoretical efficiency, which can reach the Carnot efficiency limit when operating between two thermal reservoirs.

Robert Stirling developed the cycle as an alternative to the steam engines of his time, which were prone to boiler explosions and other safety issues. His goal was to create a safer, more efficient engine that could compete with steam engines while eliminating their inherent dangers. Although the Stirling engine did not achieve widespread commercial success during the 19th century, it has experienced periodic revivals and continues to be of interest in modern applications.

The modern relevance of the Stirling cycle has been enhanced by growing interest in renewable energy sources, waste heat recovery, and environmentally friendly power generation technologies. The cycle’s ability to operate efficiently with low-grade heat sources and its inherently quiet operation make it attractive for specific applications where these characteristics are valued.

The Four Processes of the Stirling Cycle

The Stirling cycle consists of four distinct thermodynamic processes that together form a complete cycle. Each process plays a crucial role in the overall operation and efficiency of the cycle. Understanding these processes is essential for analyzing the cycle’s performance and characteristics.

Process 1-2: Isothermal Compression (Heat Rejection)

The cycle begins with isothermal compression, where the working fluid is compressed while maintaining a constant low temperature (T_L). During this process:

- Temperature remains constant at T_L (cold reservoir temperature)

- Volume decreases as the piston compresses the working fluid

- Pressure increases during the compression process

- Heat is rejected to the cold reservoir

- Work is done on the working fluid by the compressor

This process is similar to the isothermal compression in the Carnot cycle and represents the “waste heat” rejection portion of the cycle. The heat rejection during this process is necessary to maintain the constant temperature.

Process 2-3: Isochoric Heating (Constant Volume Heat Addition via Regenerator)

Following the isothermal compression, the working fluid undergoes isochoric heating, where heat is added at constant volume:

- Volume remains constant throughout the process

- Temperature increases from T_L to T_H

- Pressure increases as temperature rises (at constant volume)

- Heat is added from the regenerator or external heat source

- No work is done since volume remains constant

This isochoric heating process is a key distinguishing feature of the Stirling cycle. The heat added during this process can come from the regenerator, which stores heat from the previous cycle, or from an external heat source. This process increases the internal energy of the working fluid without changing its volume.

Process 3-4: Isothermal Expansion (Heat Addition)

The third process is isothermal expansion, where the working fluid expands while maintaining a constant high temperature (T_H):

- Temperature remains constant at T_H (hot reservoir temperature)

- Volume increases as the working fluid expands

- Pressure decreases during the expansion process

- Heat is added from the hot reservoir

- Work is done by the working fluid (power stroke)

This is the power stroke of the cycle, where the majority of the useful work is produced. It’s analogous to the isothermal expansion in the Carnot cycle and represents the energy conversion process where thermal energy is converted to mechanical work.

Process 4-1: Isochoric Cooling (Constant Volume Heat Rejection to Regenerator)

The cycle completes with isochoric cooling, where heat is rejected at constant volume:

- Volume remains constant throughout the process

- Temperature decreases from T_H to T_L

- Pressure decreases as temperature drops (at constant volume)

- Heat is rejected to the regenerator or cold reservoir

- No work is done since volume remains constant

During this final process, heat is transferred to the regenerator, which stores it for use in the next cycle’s isochoric heating process. This heat recovery mechanism is crucial for achieving the high theoretical efficiency of the Stirling cycle.

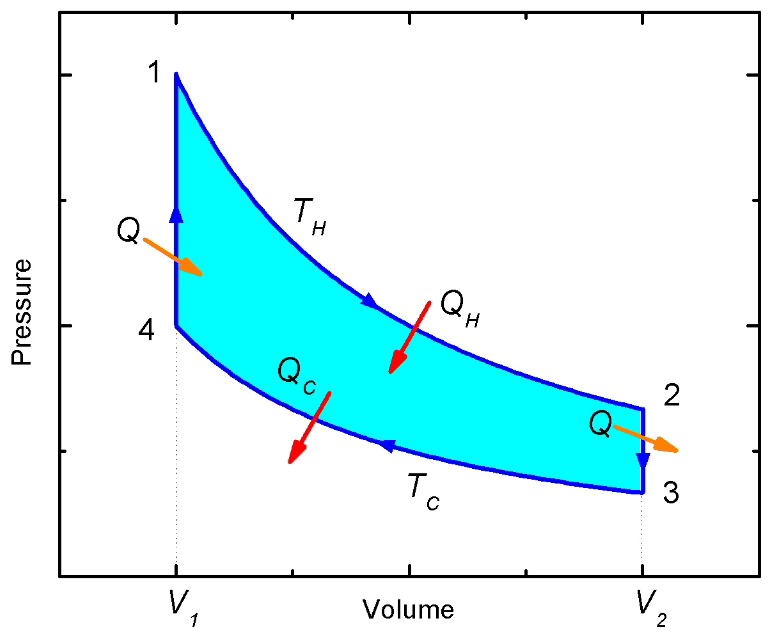

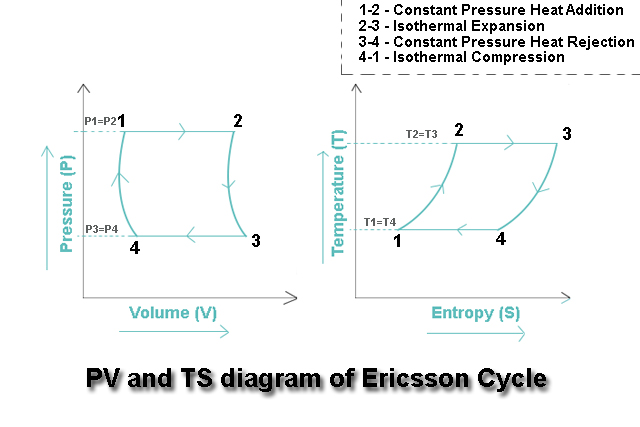

P-V (Pressure-Volume) Diagram

The Pressure-Volume (P-V) diagram is one of the most直观 ways to visualize the Stirling cycle and understand the work interactions during each process. This diagram plots pressure on the vertical axis and specific volume on the horizontal axis, providing insights into the compression and expansion work of the cycle.

Characteristics of the P-V Diagram

The P-V diagram for the Stirling cycle has several distinctive characteristics that set it apart from other thermodynamic cycles:

- Two Vertical Lines: Represent the isochoric processes (constant volume) – Process 2-3 and Process 4-1

- Two Curved Lines: Represent the isothermal processes – Process 1-2 (isothermal compression) and Process 3-4 (isothermal expansion)

- Rectangular Appearance: The combination of vertical and curved lines gives the cycle a distinctive shape

- Work Representation: The area enclosed by the cycle represents the net work output per cycle

Process Representation on P-V Diagram

Each process is represented distinctly on the P-V diagram:

- Process 1-2 (Isothermal Compression): A curve moving from lower right to upper left, showing decreasing volume and increasing pressure at constant temperature T_L

- Process 2-3 (Isochoric Heating): A vertical line moving upward, showing increasing pressure at constant volume

- Process 3-4 (Isothermal Expansion): A curve moving from upper left to lower right, showing increasing volume and decreasing pressure at constant temperature T_H

- Process 4-1 (Isochoric Cooling): A vertical line moving downward, showing decreasing pressure at constant volume

Work Calculations from P-V Diagram

The work done during each process can be determined from the P-V diagram:

- Isothermal Processes: Work is calculated using W = nRT ln(V₂/V₁)

- Isochoric Processes: No work is done since volume remains constant (W = 0)

- Net Work: The difference between work output (Process 3-4) and work input (Process 1-2), represented by the enclosed area

T-S (Temperature-Entropy) Diagram

The Temperature-Entropy (T-S) diagram provides another perspective on the Stirling cycle, emphasizing the heat transfer characteristics and entropy changes during each process. This diagram plots temperature on the vertical axis and specific entropy on the horizontal axis, making the heat transfer relationships particularly clear.

Characteristics of the T-S Diagram

The T-S diagram for the Stirling cycle has distinct characteristics that make it particularly useful for analyzing heat transfer:

- Two Horizontal Lines: Represent the isothermal processes (constant temperature) – Process 1-2 and Process 3-4

- Two Vertical Lines: Represent the isochoric processes – Process 2-3 and Process 4-1

- Rectangular Shape: With perfect processes, the cycle forms an exact rectangle on the T-S diagram

- Heat Transfer Representation: The area under each process line represents the heat transfer during that process

Process Representation on T-S Diagram

Each process has a distinctive representation on the T-S diagram:

- Process 1-2 (Isothermal Compression): A horizontal line moving leftward, showing decreasing entropy at constant temperature T_L

- Process 2-3 (Isochoric Heating): A vertical line moving upward, showing increasing entropy at increasing temperature

- Process 3-4 (Isothermal Expansion): A horizontal line moving rightward, showing increasing entropy at constant temperature T_H

- Process 4-1 (Isochoric Cooling): A vertical line moving downward, showing decreasing entropy at decreasing temperature

Heat Transfer Calculations from T-S Diagram

The heat transfer during each process can be determined from the T-S diagram:

- Isothermal Processes: Heat transfer is calculated using Q = TΔS

- Isochoric Processes: Heat transfer requires integration or use of specific heat relationships

- Net Heat Input: The difference between heat added (Processes 3-4 and 2-3) and heat rejected (Processes 1-2 and 4-1)

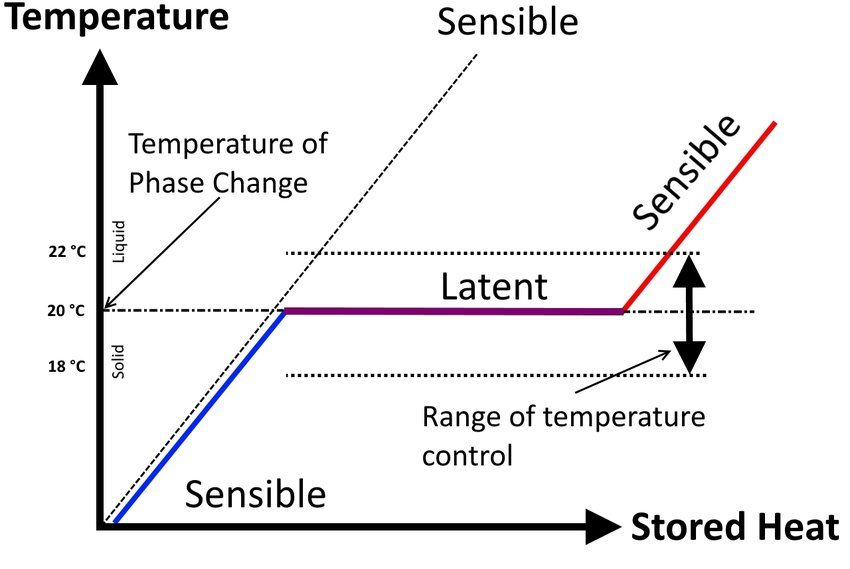

The Regenerator

The regenerator is the most crucial component of the Stirling cycle and is responsible for its high theoretical efficiency. Without an effective regenerator, the Stirling cycle would not achieve its potential performance advantages. The regenerator functions as a thermal energy storage device that recovers heat from one part of the cycle and supplies it to another part.

Principle of Operation

The regenerator operates on the principle of thermal energy storage and recovery:

- During Process 4-1 (isochoric cooling), heat is transferred from the working fluid to the regenerator material

- During Process 2-3 (isochoric heating), heat is transferred from the regenerator material back to the working fluid

- This internal heat transfer reduces the external heat input required

- In an ideal regenerator, the heat stored equals the heat recovered

The regenerator essentially acts as a thermal battery, storing energy when it’s available and releasing it when needed. This heat recovery mechanism is what allows the Stirling cycle to approach Carnot efficiency.

Regenerator Design

Effective regenerator design requires careful consideration of several factors:

- Heat Transfer Surface Area: Maximizing surface area for effective heat exchange between working fluid and regenerator material

- Thermal Mass: Sufficient thermal mass to store the required amount of energy

- Flow Distribution: Ensuring uniform flow distribution for effective heat transfer

- Pressure Drop: Minimizing pressure losses through the regenerator

- Material Selection: Choosing materials with appropriate thermal properties and compatibility with working fluid

Types of Regenerators

Several types of regenerators have been developed for Stirling engines:

- Random Pack Regenerators: Use randomly packed materials like metal screens or ceramic fibers

- Structured Regenerators: Use precisely manufactured structures like parallel plates or mesh

- Displacer Regenerators: Integrated with the displacer mechanism in some engine designs

- Rotating Regenerators: Use rotating elements to transfer heat between hot and cold sides

Regenerator Effectiveness

The effectiveness of a regenerator is a measure of how well it performs its heat recovery function:

In practical Stirling engines, regenerator effectiveness typically ranges from 80% to 95%, depending on design and operating conditions. Higher effectiveness leads to better overall cycle efficiency.

Efficiency Analysis

One of the most remarkable characteristics of the Stirling cycle is its theoretical efficiency, which can equal that of the Carnot cycle when operating between the same temperature limits and with perfect regeneration.

Theoretical Efficiency

The thermal efficiency of the ideal Stirling cycle is given by:

Where:

- η is the thermal efficiency

- T_L is the absolute temperature of the cold reservoir

- T_H is the absolute temperature of the hot reservoir

This is identical to the Carnot efficiency, making the Stirling cycle theoretically as efficient as possible for any heat engine operating between the same temperature limits.

Factors Affecting Practical Efficiency

While the theoretical efficiency matches the Carnot efficiency, practical implementations face several challenges:

- Regenerator Effectiveness: Imperfect heat exchange in regenerators reduces efficiency

- Pressure Drops: Friction losses in heat exchangers and piping

- Heat Transfer Limitations: Finite heat transfer rates affect cycle performance

- Working Fluid Properties: Real gas behavior deviates from ideal assumptions

- Mechanical Losses: Friction and other mechanical losses in moving parts

Comparison with Other Cycles

Comparing the Stirling cycle with other thermodynamic cycles:

| Cycle | Processes | Theoretical Efficiency | Comments |

|---|---|---|---|

| Carnot | 2 Isothermal, 2 Isentropic | η = 1 – (T_L / T_H) | Maximum possible efficiency |

| Stirling | 2 Isothermal, 2 Isochoric | η = 1 – (T_L / T_H) | Equals Carnot efficiency with perfect regeneration |

| Ericsson | 2 Isothermal, 2 Isobaric | η = 1 – (T_L / T_H) | Equals Carnot efficiency |

| Rankine | 2 Isobaric, 2 Isentropic | Less than Carnot | Practical steam cycle |

| Brayton | 2 Isobaric, 2 Isentropic | Less than Carnot | Gas turbine cycle |

Applications and Implementations

The Stirling cycle has found applications in various fields, from specialized power generation to cryogenic cooling systems. While it has not achieved the widespread commercial success of other cycles, its unique characteristics make it suitable for specific applications where its advantages outweigh its disadvantages.

Power Generation Applications

Stirling engines have been used in various power generation applications:

- Solar Power: Concentrated solar Stirling systems for electricity generation

- Waste Heat Recovery: Converting waste heat from industrial processes to useful power

- Remote Power: Generating electricity in remote locations where conventional power sources are unavailable

- Combined Heat and Power (CHP): Simultaneous generation of electricity and useful heat

Cryogenic Applications

The Stirling cycle is particularly well-suited for cryogenic applications:

- Cryocoolers: Refrigeration systems for cooling to very low temperatures

- Liquefaction: Converting gases to liquid form for storage and transport

- Scientific Instruments: Providing cooling for sensitive scientific equipment

- Medical Applications: Cryogenic preservation and treatment systems

Marine Applications

Stirling engines have been investigated for marine applications:

- Submarine Propulsion: Quiet operation makes Stirling engines attractive for military submarines

- Auxiliary Power: Providing power for shipboard systems

- Hybrid Systems: Integration with other marine propulsion systems

Space Applications

The Stirling cycle has been considered for space applications:

- Radioisotope Power Systems: Converting heat from radioactive decay to electricity for spacecraft

- Solar Power in Space: Utilizing concentrated solar energy in space environments

Advantages of the Stirling Cycle

The Stirling cycle offers several significant advantages that make it attractive for specific applications:

- High Theoretical Efficiency: Can achieve Carnot efficiency with perfect regeneration

- Fuel Flexibility: Can use virtually any heat source including solar, biomass, and waste heat

- Low Emissions: External combustion allows for cleaner burning and better emission control

- Quiet Operation: Inherently quieter than internal combustion engines due to external heat addition

- Low Vibration: Balanced operation results in minimal vibration

- Reliability: Fewer moving parts compared to some other engine types

Disadvantages and Challenges

Despite its advantages, the Stirling cycle also faces several challenges that have limited its widespread adoption:

- Complexity: Requires sophisticated regenerator design and manufacturing

- Cost: Higher initial cost compared to simpler engines

- Size and Weight: Can be bulky for the power output achieved

- Start-up Time: Longer start-up time due to the need to heat the regenerator

- Maintenance: Regenerators may require periodic cleaning or replacement

- Transient Response: Slower response to load changes compared to internal combustion engines

Mathematical Analysis

A detailed mathematical analysis of the Stirling cycle provides quantitative insights into its performance characteristics.

Work and Heat Calculations

For an ideal Stirling cycle with perfect regeneration:

Work during isothermal compression (Process 1-2):

Work during isothermal expansion (Process 3-4):

Work during isochoric processes (Process 2-3 and 4-1):

Net work output:

Heat Transfer Calculations

Heat transfer during isothermal processes:

With perfect regeneration, the heat transfer during isochoric processes cancels out:

Efficiency Calculation

Thermal efficiency:

Substituting the heat transfer expressions:

For an ideal cycle with V₁/V₂ = V₄/V₃:

Modern Developments and Research

Recent research has focused on improving Stirling cycle performance and expanding its applications.

Advanced Materials

New materials have the potential to improve Stirling cycle performance:

- High-Temperature Alloys: Materials that can withstand repeated thermal cycling

- Advanced Ceramics: For high-temperature regenerator applications

- Nanomaterials: For improved heat transfer characteristics

- Phase Change Materials: For enhanced thermal energy storage

Computational Modeling

Advanced computational tools have enabled more detailed analysis:

- CFD Analysis: Computational fluid dynamics for optimizing flow patterns

- Thermodynamic Simulation: Detailed cycle modeling including irreversibilities

- Optimization Algorithms: Finding optimal operating conditions and designs

Hybrid Systems

Integration with other technologies offers new possibilities:

- Combined Cycles: Integration with Brayton or Rankine cycles

- Renewable Energy Systems: Coupling with solar or geothermal sources

- Waste Heat Recovery: Utilization of industrial waste heat streams

Conclusion

The Stirling cycle represents one of the most theoretically efficient thermodynamic cycles, offering the potential to achieve Carnot efficiency through the use of regeneration. Its unique combination of two isothermal processes and two isochoric processes, along with the crucial regenerator component, distinguishes it from other thermodynamic cycles and provides its performance advantages.

The cycle’s representation on P-V and T-S diagrams clearly illustrates its characteristics and helps in understanding the work and heat transfer interactions. The rectangular appearance on T-S diagrams with perfect processes highlights the cycle’s efficiency potential, while the distinctive shape on P-V diagrams shows the constant volume processes that are key to its operation.

The regenerator is the heart of the Stirling cycle, enabling the high theoretical efficiency by recovering heat that would otherwise be rejected. The design and effectiveness of the regenerator are crucial factors in determining the practical performance of Stirling engines.

Despite its theoretical advantages, the Stirling cycle has faced practical challenges that have limited its widespread commercial adoption. The complexity of implementing effective regenerators, the higher initial costs, and the difficulty in handling transient operations have all contributed to its limited use compared to simpler cycles like the Rankine or Brayton cycles.

However, the fundamental principles of the Stirling cycle continue to be relevant in modern thermal engineering. The cycle’s high theoretical efficiency, fuel flexibility, and low emission characteristics make it attractive for specific applications where these advantages outweigh the disadvantages.

Recent advances in materials science, computational modeling, and hybrid system design offer new possibilities for implementing Stirling cycle principles in modern applications. The cycle’s potential for integration with renewable energy sources, waste heat recovery systems, and cryogenic applications suggests that it may find new relevance in sustainable energy systems.

For students and practitioners of thermal engineering, understanding the Stirling cycle provides valuable insights into the fundamental limits of heat engine performance and the various approaches to achieving high efficiency. The mathematical analysis reveals the relationships between operating conditions, work output, and efficiency, while the thermodynamic diagrams provide visual tools for understanding cycle behavior.

As energy systems continue to evolve toward greater efficiency and sustainability, the principles embodied in the Stirling cycle remain relevant. The cycle’s emphasis on regeneration and external heat exchange aligns with modern goals of energy recovery and efficient resource utilization.

In conclusion, while the Stirling cycle may not be widely used in commercial applications today, its theoretical foundations and underlying principles continue to inform the development of advanced thermal systems. Understanding this cycle contributes to a comprehensive knowledge of thermodynamic cycles and their potential for energy conversion applications.