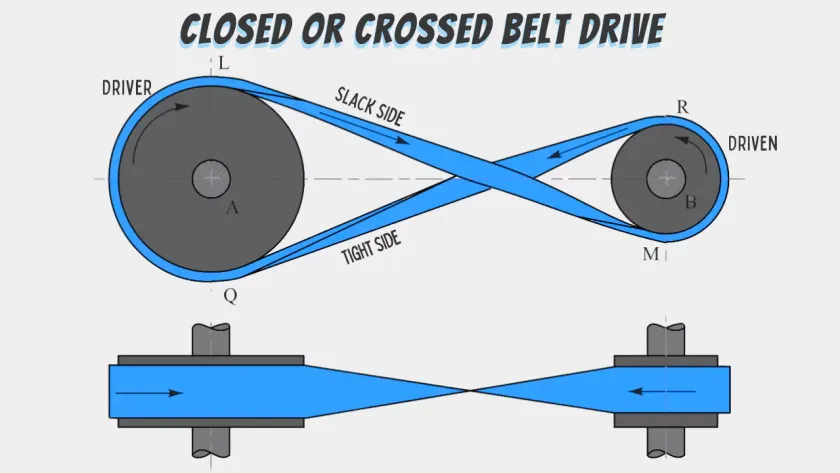

In the field of mechanical engineering and maintenance, belt drives represent one of the most widely used and versatile methods for transmitting power between rotating shafts. These flexible power transmission systems have been fundamental to industrial machinery since the early days of mechanization and continue to play a crucial role in modern manufacturing, transportation, and automation systems.

Belt drives offer numerous advantages including simplicity, cost-effectiveness, flexibility in shaft arrangement, overload protection, and noise reduction compared to other power transmission methods. Understanding the various types of belt drives and their specific applications is essential for engineers, designers, and maintenance professionals who work with mechanical power transmission systems.

Introduction to Belt Drives

Belt drives are mechanical power transmission systems that use flexible belts to transfer rotational motion and torque between shafts. They operate on the principle of friction or positive engagement between the belt and pulleys (sheaves) to transmit power efficiently over distances that would be impractical or impossible with direct mechanical connections.

The fundamental concept of belt drives dates back centuries, with early applications using leather belts in textile mills and early industrial machinery. Modern belt drives have evolved significantly, incorporating advanced materials, precision manufacturing, and sophisticated design principles that enable them to handle high power transmission requirements with exceptional reliability and efficiency.

Belt drives offer several key advantages that make them attractive for numerous applications:

- Flexibility: Can accommodate various shaft arrangements including parallel, angular, and crossed configurations

- Overload Protection: Belts slip under excessive loads, protecting machinery from damage

- Noise Reduction: Operate more quietly than gear or chain drives

- Cost-Effectiveness: Generally less expensive than alternative power transmission methods

- Maintenance Simplicity: Require minimal maintenance compared to geared systems

- Vibration Damping: Flexible elements absorb vibration and shock loads

These characteristics, combined with continuous improvements in belt materials and design, have made belt drives indispensable in modern mechanical systems across numerous industries.

Classification of Belt Drives

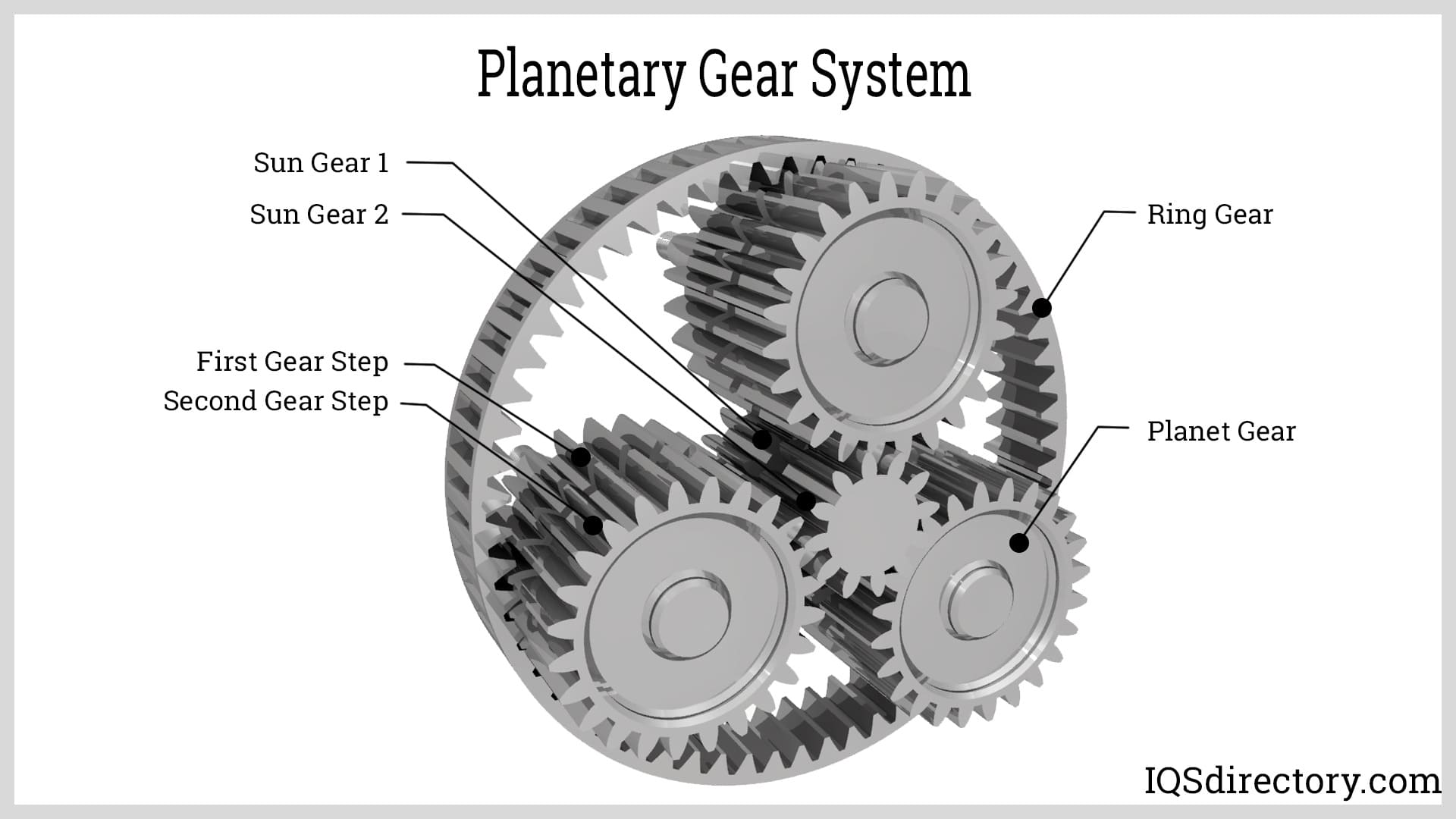

Belt drives can be classified in several ways based on different criteria including power transmission method, belt construction, and application requirements. Understanding these classifications helps in selecting the appropriate belt drive system for specific applications.

By Power Transmission Method

The primary classification of belt drives is based on how power is transmitted from the driving pulley to the driven pulley:

- Friction Belt Drives: Power is transmitted through friction between the belt and pulley surfaces

- Positive Belt Drives: Power is transmitted through positive engagement between belt teeth and pulley grooves

By Belt Construction

Belt drives can also be classified based on the construction and materials used in the belt:

- Flat Belts: Smooth, flat belts that rely on friction for power transmission

- V-Belts: Trapezoidal cross-section belts that wedge into pulley grooves

- Round Belts: Circular cross-section belts used for light-duty applications

- Timing Belts: Belts with teeth that positively engage with toothed pulleys

- Ribbed Belts: Belts with multiple V-shaped ribs for improved power transmission

By Application Requirements

Classification based on specific application needs includes:

- Light-Duty Drives: For low-power applications with minimal load requirements

- Medium-Duty Drives: For general industrial applications with moderate power and load requirements

- Heavy-Duty Drives: For high-power applications with substantial load requirements

- High-Speed Drives: For applications requiring high rotational speeds

- Precision Drives: For applications requiring accurate speed ratios and minimal slip

Flat Belt Drives

Flat belt drives represent one of the oldest and most fundamental forms of belt drive systems. These drives use smooth, flat belts that transmit power through friction between the belt surface and pulley faces.

Construction and Characteristics

Flat belts are constructed with multiple layers of materials that provide strength, flexibility, and durability:

Key construction features include:

- Fabric Layers: Multiple plies of cotton, polyester, or synthetic fabrics provide tensile strength

- Rubber Covering: Protective rubber compound provides friction surface and environmental resistance

- Reinforcement Cords: High-strength cords embedded in the belt body for load carrying

- Edge Reinforcement: Special treatment of belt edges to prevent fraying and damage

Advantages

Flat belt drives offer several advantages that make them suitable for specific applications:

- High Efficiency: Can achieve efficiencies of 98% or higher due to minimal sliding

- High Speed Capability: Suitable for very high-speed applications

- Flexibility: Can accommodate large center distances and various shaft arrangements

- Quiet Operation: Extremely quiet operation with minimal vibration

- Cost-Effective: Lower initial cost compared to other belt types for large drives

Disadvantages

Despite their advantages, flat belt drives also have notable disadvantages:

- Slippage: Prone to slipping under heavy loads or when contaminated

- Misalignment Sensitivity: Highly sensitive to pulley misalignment

- Limited Power Transmission: Lower power transmission capacity compared to V-belts

- Maintenance Requirements: Require regular tension adjustment and alignment checks

- Environmental Sensitivity: Performance affected by temperature, humidity, and contamination

Applications

Flat belt drives find applications in situations where their specific characteristics are advantageous:

- Textile Machinery: High-speed textile equipment requiring quiet operation

- Paper Mills: Large paper processing machinery with long center distances

- Woodworking Equipment: High-speed woodworking machinery

- Agricultural Machinery: Farm equipment with variable operating conditions

- Historical Restoration: Vintage machinery restoration projects

V-Belt Drives

V-belt drives represent the most common type of belt drive system in modern industrial applications. These drives use belts with a trapezoidal cross-section that wedge into correspondingly shaped pulley grooves, creating a wedging action that significantly increases power transmission capacity compared to flat belts.

Construction and Characteristics

V-belts are constructed with specialized materials and geometries designed to maximize the wedging action and power transmission efficiency:

Key construction features include:

- Trapezoidal Cross-Section: Standardized angle (typically 40°) for optimal wedging action

- Tensile Members: High-strength cords (polyester, aramid, or steel) for load carrying

- Compression Rubber: Rubber compound in the compression zone for flexibility

- Cover Rubber: Wear-resistant rubber covering for protection and friction

- Reinforced Edges: Special edge treatment to prevent fraying and damage

Advantages

V-belt drives offer numerous advantages that have made them the standard for most industrial applications:

- High Power Transmission: Significantly higher power transmission capacity than flat belts

- Reduced Slippage: Wedging action minimizes slippage under normal operating conditions

- Easy Installation: Simple installation and replacement procedures

- Standardization: Widely standardized sizes and dimensions for interchangeability

- Versatility: Suitable for a wide range of power and speed requirements

- Cost-Effectiveness: Excellent power-to-cost ratio for most applications

Disadvantages

V-belt drives also have certain limitations that must be considered:

- Speed Limitations: Not suitable for extremely high-speed applications

- Heat Generation: Friction can generate significant heat at high loads

- Wear Characteristics: Subject to wear that affects performance over time

- Misalignment Sensitivity: Performance affected by pulley misalignment

- Slip Under Extreme Loads: Will slip under excessive loads, potentially causing speed variations

Types of V-Belts

V-belts are available in several standardized types to meet different power transmission requirements:

| Type | Power Range | Speed Range | Applications |

|---|---|---|---|

| Classical V-Belts (A, B, C, D, E) | 0.2 – 500 HP | 500 – 8,000 RPM | General industrial machinery |

| Narrow V-Belts (3V, 5V, 8V) | 1 – 1,000 HP | 1,000 – 10,000 RPM | High-power industrial drives |

| Light-Duty V-Belts (Z, A, B) | 0.05 – 5 HP | 100 – 5,000 RPM | Small machinery, appliances |

| Banded V-Belts | 0.5 – 200 HP | 500 – 6,000 RPM | Fan drives, pumps, compressors |

Applications

V-belt drives are used in countless applications across numerous industries:

- Automotive: Engine accessories, air conditioning compressors, water pumps

- Industrial Machinery: Pumps, fans, compressors, conveyors

- Agricultural Equipment: Tractors, harvesters, irrigation systems

- Construction Equipment: Excavators, bulldozers, concrete mixers

- Consumer Appliances: Washing machines, dryers, vacuum cleaners

Timing Belt Drives

Timing belt drives, also known as synchronous belt drives, represent a specialized category of belt drives that provide positive engagement between the belt and pulleys through precisely machined teeth. These drives combine the flexibility and quiet operation of belt drives with the positive engagement characteristics of gear drives.

Construction and Characteristics

Timing belts are constructed with precision-engineered teeth that mesh with corresponding grooves in specially designed pulleys:

Key construction features include:

- Precise Tooth Profile: Standardized tooth shapes (trapezoidal, curvilinear, or modified curvilinear)

- High-Strength Cords: Glass fiber, aramid, or steel cords for load carrying

- Specialized Rubber Compounds: Neoprene or polyurethane cover materials for durability

- Precision Pulleys: Specially machined pulleys with matching tooth profiles

- Reinforced Back: Additional reinforcement for dimensional stability

Advantages

Timing belt drives offer unique advantages that make them suitable for precision applications:

- Zero Slip: Positive engagement eliminates slip under normal operating conditions

- Precise Speed Ratios: Exact speed ratios maintained without variation

- Quiet Operation: Extremely quiet operation compared to chain or gear drives

- Low Maintenance: Require minimal maintenance beyond periodic inspection

- No Lubrication: Do not require lubrication, reducing maintenance costs

- High Efficiency: Can achieve efficiencies of 98% or higher

Disadvantages

Timing belt drives also have certain limitations that must be considered:

- Shock Load Sensitivity: Cannot slip to protect machinery under excessive loads

- Higher Initial Cost: More expensive than friction belt drives

- Precision Requirements: Require precise alignment and tensioning

- Environmental Sensitivity: Performance affected by contaminants and extreme temperatures

- Wear Characteristics: Tooth wear can affect timing accuracy over time

Types of Timing Belts

Timing belts are available in various configurations to meet different application requirements:

| Type | Tooth Profile | Power Range | Applications |

|---|---|---|---|

| Trapezoidal Tooth | Standard trapezoidal shape | 0.1 – 200 HP | General precision drives |

| Curvilinear Tooth | Curved tooth profile | 0.5 – 500 HP | High-power precision applications |

| Modified Curvilinear | Optimized curved profile | 1 – 1,000 HP | Ultra-high precision drives |

| HTD (High Torque Drive) | Round tooth profile | 0.5 – 300 HP | High-torque applications |

Applications

Timing belt drives are used in applications where precise speed control and high reliability are required:

- Machine Tools: CNC machines, lathes, milling machines requiring precise positioning

- Automotive Engines: Camshaft drives in modern engines

- Printing Presses: Paper feed and registration systems requiring exact timing

- Robotics: Precision joint drives in robotic systems

- Medical Equipment: Diagnostic and therapeutic equipment requiring precise motion control

- Aerospace: Precision actuation systems in aircraft and spacecraft

Round Belt Drives

Round belt drives represent a specialized category of belt drives that use circular cross-section belts for specific low-power applications. These drives are characterized by their simplicity and are typically used in applications where power transmission requirements are minimal but precise positioning or synchronization is not critical.

Construction and Characteristics

Round belts are constructed with simple circular cross-sections that can be made from various materials:

Key construction features include:

- Circular Cross-Section: Uniform diameter throughout the belt length

- Material Options: Rubber, polyurethane, or synthetic materials

- Simple Construction: Minimal layers or reinforcement for cost-effectiveness

- Standard Sizes: Available in standard diameters for interchangeability

Advantages

Round belt drives offer specific advantages for limited applications:

- Simplicity: Extremely simple construction and installation

- Low Cost: Inexpensive compared to other belt types

- Flexibility: Highly flexible for accommodating misalignment

- Quiet Operation: Very quiet operation with minimal vibration

- Lightweight: Minimal weight addition to mechanical systems

Disadvantages

Round belt drives have significant limitations that restrict their applications:

- Low Power Capacity: Very limited power transmission capability

- High Slippage: Significant slippage under even moderate loads

- Poor Efficiency: Low efficiency due to high slip losses

- Limited Speed Range: Not suitable for high-speed applications

- Short Service Life: Limited durability compared to other belt types

Applications

Round belt drives find applications in specific low-power scenarios:

- Household Appliances: Small appliances with minimal power requirements

- Office Equipment: Typewriters, calculators, and small office machines

- Toy Manufacturing: Mechanical toys and educational models

- Light Industrial Equipment: Small conveyors and material handling systems

- Historical Machinery: Restoration of vintage mechanical devices

Ribbed Belt Drives

Ribbed belt drives, also known as poly-V or multi-V belt drives, represent a modern advancement in belt drive technology that combines the advantages of V-belts with enhanced power transmission capabilities and improved flexibility. These belts feature multiple narrow V-shaped ribs that engage with specially designed pulley grooves.

Construction and Characteristics

Ribbed belts are constructed with multiple narrow V-shaped ribs that provide enhanced contact area and power transmission:

Key construction features include:

- Multiple Ribs: 3 to 20 or more narrow V-shaped ribs for increased contact area

- High-Strength Cords: Polyester or aramid tensile members for load carrying

- Specialized Rubber Compounds: High-performance materials for durability and flexibility

- Precision Pulleys: Specially designed pulleys with matching rib profiles

- Enhanced Flexibility: Improved flexibility compared to classical V-belts

Advantages

Ribbed belt drives offer several advantages that make them suitable for demanding applications:

- High Power Density: Exceptional power transmission capacity for their size

- Improved Flexibility: Better flexibility than classical V-belts for smaller pulleys

- Reduced Heat Generation: Lower heat generation due to reduced sliding

- Enhanced Efficiency: Higher efficiency compared to classical V-belts

- Better Load Distribution: Multiple ribs distribute loads more evenly

- Reduced Vibration: Smoother operation with reduced vibration characteristics

Disadvantages

Ribbed belt drives also have certain limitations:

- Higher Initial Cost: More expensive than classical V-belts

- Precision Requirements: Require precise pulley matching and alignment

- Limited Availability: Less widely available than classical V-belts

- Specialized Maintenance: Require specialized knowledge for installation and maintenance

Applications

Ribbed belt drives are used in applications requiring high power density and precision:

- Automotive: Engine accessory drives in modern vehicles

- Motorcycles: Camshaft and accessory drives in motorcycle engines

- Industrial Machinery: High-power industrial drives with space constraints

- Agricultural Equipment: Compact high-power drives in farm machinery

- Construction Equipment: Accessory drives in compact construction machinery

Design Considerations

Proper design of belt drive systems requires careful consideration of numerous factors that influence performance, reliability, and cost-effectiveness.

Power and Speed Requirements

The power and speed requirements of the application are primary factors in belt drive selection:

- Power Transmission: Required horsepower or kilowatt rating determines belt type and size

- Speed Ratios: Desired speed ratios influence pulley selection and arrangement

- Operating Speeds: Maximum speeds affect belt type and material selection

- Load Characteristics: Nature of loads (constant, variable,冲击) affects drive design

Environmental Factors

Environmental conditions significantly influence belt drive performance and selection:

- Temperature Extremes: Operating temperatures affect material selection and performance

- Humidity and Moisture: Wet or humid environments require special belt materials

- Chemical Exposure: Chemical environments may require chemical-resistant belts

- Dust and Contamination: Contaminated environments affect belt life and performance

- UV Exposure: Outdoor applications require UV-resistant belt materials

Maintenance Requirements

Maintenance considerations affect the selection and design of belt drive systems:

- Accessibility: Easy access for inspection, adjustment, and replacement

- Service Intervals: Required maintenance frequency affects belt type selection

- Spare Parts Availability: Availability of replacement belts and components

- Skilled Labor: Availability of trained personnel for maintenance activities

Maintenance and Troubleshooting

Proper maintenance of belt drive systems is essential for achieving optimal performance and service life.

Routine Maintenance

Regular maintenance activities help ensure reliable belt drive operation:

- Visual Inspection: Regular visual checks for wear, damage, or contamination

- Tension Checks: Periodic tension verification and adjustment

- Alignment Verification: Checking and maintaining proper pulley alignment

- Lubrication: Lubricating bearings and checking lubricant condition

- Cleanliness: Keeping belts and pulleys clean and free from contaminants

Common Problems and Solutions

Understanding common belt drive problems helps in developing effective troubleshooting strategies:

| Problem | Cause | Solution |

|---|---|---|

| Belt Slipping | Insufficient tension, worn belts, contaminated pulleys | Adjust tension, replace belts, clean pulleys |

| Excessive Noise | Misalignment, worn components, improper tension | Check alignment, replace worn parts, adjust tension |

| Premature Wear | Overloading, misalignment, contamination, improper tension | Reduce loads, correct alignment, clean system, adjust tension |

| Belt Breakage | Shock loading, over-tensioning, material fatigue | Install shock absorbers, adjust tension, replace belts |

| Speed Variations | Belt stretch, slippage, worn pulleys | Replace stretched belts, adjust tension, replace pulleys |

Selection Criteria

Proper selection of belt drive systems requires careful evaluation of multiple factors to ensure optimal performance and cost-effectiveness.

Power Requirements

Power transmission requirements are fundamental to belt drive selection:

- Required Horsepower: Determine the exact power requirements of the driven equipment

- Service Factor: Apply appropriate service factors for load characteristics and operating conditions

- Peak Loads: Consider maximum loads that may occur during operation

- Duty Cycle: Account for continuous versus intermittent operation requirements

Speed and Ratio Requirements

Speed and ratio requirements influence belt type and size selection:

- Input Speed: Driving shaft speed affects belt type selection

- Output Speed: Driven shaft speed requirements determine speed ratios

- Speed Range: Operating speed range affects belt performance characteristics

- Precision Requirements: Exact speed ratios may require timing belts

Environmental and Operational Factors

Environmental and operational factors significantly influence belt drive selection:

- Operating Environment: Indoor, outdoor, clean, or contaminated environments

- Temperature Range: Ambient and operating temperature extremes

- Chemical Exposure: Presence of chemicals, oils, or solvents

- Maintenance Accessibility: Ease of access for inspection and maintenance

- Noise Restrictions: Sound level requirements for the application

Sample Problems and Calculations

Working through sample problems helps illustrate the practical application of belt drive principles and calculations.

Problem 1: V-Belt Power Transmission

A V-belt drive system needs to transmit 15 kW of power from a motor running at 1,800 rpm to a driven machine running at 600 rpm. The service factor is 1.3. Select an appropriate V-belt type and determine the required number of belts.

Given:

- Power = 15 kW

- Motor Speed = 1,800 rpm

- Driven Machine Speed = 600 rpm

- Service Factor = 1.3

Solution:

First, calculate the design power:

Calculate the speed ratio:

Based on the design power of 19.5 kW and typical V-belt capacity charts, a B-series or 5V narrow V-belt would be appropriate. Assuming a B-series belt with a capacity of approximately 5 kW per belt at the operating conditions:

Therefore, four B-series V-belts would be required to transmit the required power with an appropriate safety margin.

Problem 2: Timing Belt Speed Ratio

A timing belt drive connects two shafts with a speed ratio of 2:1. The driving pulley has 36 teeth. Calculate the number of teeth on the driven pulley and the linear belt speed if the driving shaft rotates at 1,200 rpm and the pitch diameter of the driving pulley is 72 mm.

Given:

- Speed Ratio = 2:1 (driving:driven)

- Driving Pulley Teeth (T₁) = 36

- Driving Shaft Speed (N₁) = 1,200 rpm

- Driving Pulley Pitch Diameter (D₁) = 72 mm

Solution:

First, calculate the driven pulley teeth:

Calculate the driven shaft speed:

Calculate the linear belt speed:

Therefore, the driven pulley has 72 teeth, the driven shaft rotates at 600 rpm, and the linear belt speed is 4.52 m/s.

Problem 3: Belt Tension Calculation

A V-belt drive transmits 7.5 kW of power at a belt speed of 15 m/s. The coefficient of friction between the belt and pulley is 0.3. Calculate the tight side tension and slack side tension assuming the belt is operating at optimum conditions.

Given:

- Power = 7.5 kW = 7,500 W

- Belt Speed (V) = 15 m/s

- Coefficient of Friction (μ) = 0.3

Solution:

First, calculate the effective tension:

For optimum conditions, the relationship between tight side tension (T₁) and slack side tension (T₂) is:

And the Euler equation for belt friction:

Assuming a wrap angle (θ) of 180° = π radians:

Solving the simultaneous equations:

Therefore, the tight side tension is 819.3 N and the slack side tension is 319.3 N.

Conclusion

Belt drives represent one of the most versatile and widely used methods of mechanical power transmission, offering an optimal balance of simplicity, cost-effectiveness, and performance for countless applications across numerous industries. The comprehensive understanding of the various types of belt drives and their specific characteristics enables engineers and maintenance professionals to make informed decisions that optimize system performance while meeting operational and economic requirements.

The evolution from simple flat belt drives to sophisticated timing and ribbed belt systems demonstrates the continuous advancement in belt drive technology. Each type of belt drive offers unique advantages that make it suitable for specific applications, from the high-efficiency flat belts used in textile machinery to the precision timing belts essential in modern CNC machine tools and robotics.

V-belt drives have emerged as the standard for most industrial applications due to their excellent power transmission capacity, reliability, and cost-effectiveness. Their widespread adoption is justified by the optimal combination of characteristics they provide, making them suitable for everything from small household appliances to large industrial machinery.

Timing belt drives offer the unique advantage of positive engagement that eliminates slip and ensures precise speed ratios, making them indispensable in applications requiring exact timing and positioning. Their quiet operation and low maintenance requirements further enhance their appeal for precision applications.

The specialized applications of round belt drives and ribbed belt drives demonstrate the diversity of belt drive technology. While round belts serve specific low-power applications with minimal requirements, ribbed belts provide exceptional power density for applications where space and weight are critical constraints.

The sample problems illustrate the practical application of belt drive calculations, showing how power transmission requirements, speed ratios, and tension calculations guide the selection and design of belt drive systems. These quantitative relationships provide the foundation for informed engineering decisions and system optimization.

Design considerations emphasize the importance of evaluating multiple factors including power requirements, environmental conditions, and maintenance accessibility when selecting belt drive systems. The proper selection of belt type, size, and configuration significantly affects system performance, reliability, and total cost of ownership.

Maintenance and troubleshooting procedures are essential for achieving optimal belt drive performance and service life. Regular inspection, proper tensioning, and alignment maintenance prevent common problems and extend system life. Understanding failure modes and their causes enables proactive maintenance strategies that minimize downtime and repair costs.

The selection criteria framework provides a systematic approach for evaluating belt drive options based on specific application requirements. This methodology ensures that the chosen belt drive system optimally balances performance, reliability, and cost considerations.

For students and practitioners of mechanical engineering and maintenance, mastering the principles of belt drive systems provides essential knowledge for successful system design, operation, and maintenance. The combination of theoretical understanding with practical application considerations prepares professionals to make informed decisions about power transmission solutions.

As technology continues to advance, belt drive systems are benefiting from improvements in materials science, manufacturing precision, and design optimization techniques. These developments are enhancing the already impressive capabilities of belt drives while potentially reducing some of their traditional disadvantages.

Looking forward, emerging technologies such as smart materials, condition monitoring systems, and advanced manufacturing techniques promise to further expand the capabilities and applications of belt drives. These developments may enable new design possibilities and performance levels that could redefine the role of belt drives in mechanical systems.

In conclusion, belt drives represent a mature yet evolving technology that continues to provide exceptional value in power transmission applications. Their unique combination of characteristics makes them irreplaceable in many critical applications, and their continued development promises even greater capabilities for future engineering challenges. Understanding these systems is essential for any professional working in mechanical design, power transmission, or maintenance of rotating machinery.