In the field of mechanical engineering and maintenance, rolling element bearings are among the most critical components in machinery and equipment. These precision components enable smooth rotational motion while supporting radial and axial loads in countless applications, from automotive wheel hubs to industrial turbines. Understanding bearing numbers is essential for engineers, maintenance personnel, and procurement specialists to ensure proper selection, replacement, and maintenance of these vital components.

Bearing numbers, also known as bearing designations or part numbers, provide a standardized system for identifying and specifying rolling element bearings. This numbering system contains crucial information about the bearing’s type, dimensions, design features, and special characteristics. Proper interpretation of bearing numbers is fundamental to avoiding costly mistakes in bearing selection and replacement, which can lead to equipment failure, unplanned downtime, and safety hazards.

Introduction to Bearing Numbers

Bearing numbers serve as a universal language in the bearing industry, allowing engineers and technicians worldwide to communicate specific bearing requirements without ambiguity. These standardized designations have been developed by bearing manufacturers and industry organizations to ensure consistency and accuracy in bearing identification.

The importance of understanding bearing numbers cannot be overstated in engineering maintenance and machinery operation. Incorrect bearing selection due to misinterpretation of bearing numbers can result in:

- Premature bearing failure

- Equipment downtime and production losses

- Safety hazards due to unexpected equipment failure

- Increased maintenance costs

- Reduced equipment life

The standardized numbering system enables precise communication between equipment manufacturers, bearing suppliers, maintenance personnel, and engineers. This system is particularly important when sourcing replacement bearings, as even slight dimensional or design differences can lead to catastrophic failures.

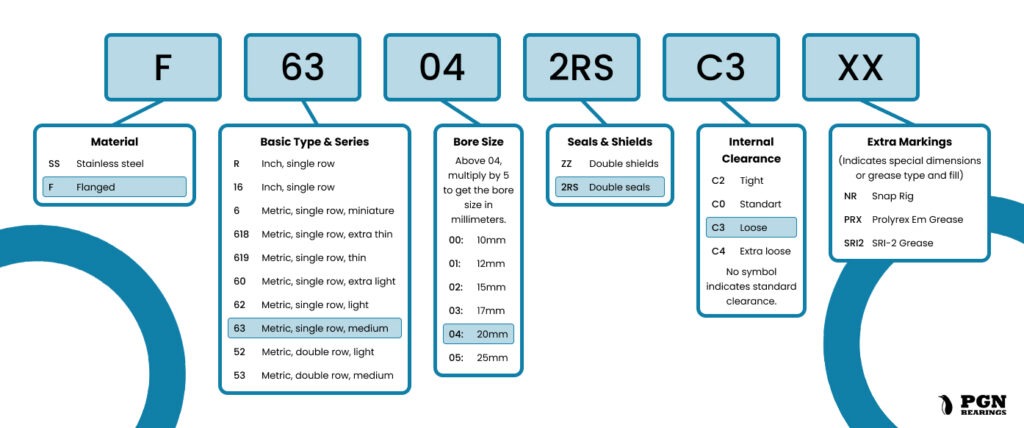

The Basic Bearing Designation

The basic bearing designation typically consists of a series of digits that encode essential information about the bearing. The most common format used by major bearing manufacturers like SKF, NSK, NTN, and FAG follows a standardized structure, though there may be slight variations between manufacturers.

A typical basic bearing designation consists of at least four digits, each with a specific meaning:

For example, in the bearing designation “6205”:

- First Digit (6): Bearing Type – Deep Groove Ball Bearing

- Second Digit (2): Dimension Series – Width and diameter series

- Third & Fourth Digits (05): Bore Size Code – 5 × 5 = 25 mm bore diameter

Bearing Type Identification

The first digit (or sometimes first two digits) of a bearing designation typically indicates the bearing type. The most common bearing types include:

- 1: Self-aligning ball bearing

- 2: Cylindrical roller bearing

- 3: Tapered roller bearing

- 5: Thrust ball bearing

- 6: Deep groove ball bearing (most common)

- 7: Angular contact ball bearing

- N: Cylindrical roller bearing (metric series)

Dimension Series

The second digit in the basic designation represents the dimension series, which relates to the bearing’s width and outside diameter for a given bore size. This series designation is crucial for ensuring proper fit and load capacity.

The dimension series consists of two components:

- Width Series: Indicates the bearing’s width or height

- Diameter Series: Indicates the bearing’s outside diameter

Common dimension series designations include:

- 0: Extra light series

- 1: Light series

- 2: Medium series

- 3: Medium heavy series

- 4: Heavy series

Bore Size Code

The last two digits of the basic bearing designation represent the bore size code. This is perhaps the most critical piece of information, as it determines whether the bearing will properly fit on the shaft.

The bore size calculation follows a standard rule:

However, there are important exceptions for small bore sizes:

- 00: Bore diameter = 10 mm

- 01: Bore diameter = 12 mm

- 02: Bore diameter = 15 mm

- 03: Bore diameter = 17 mm

- 04 and above: Bore diameter = Code × 5 mm

For example:

- 6200: Bore = 10 mm (00 = 10 mm)

- 6201: Bore = 12 mm (01 = 12 mm)

- 6202: Bore = 15 mm (02 = 15 mm)

- 6203: Bore = 17 mm (03 = 17 mm)

- 6204: Bore = 20 mm (04 × 5 = 20 mm)

- 6205: Bore = 25 mm (05 × 5 = 25 mm)

Common Prefixes and Suffixes

Beyond the basic four-digit designation, bearings often include prefixes and suffixes that provide additional information about special features, materials, design modifications, and performance characteristics. Understanding these additions is crucial for proper bearing selection and application.

Prefixes

Prefixes are typically used to indicate special components or materials used in bearing construction:

- S: Stainless steel (commonly used for corrosion resistance)

- W: Special materials or coatings

- E: Enhanced design or improved performance characteristics

- Z: Thrust washers or special thrust components

These prefixes are particularly important in applications where environmental conditions or special operating requirements demand specific bearing characteristics.

Suffixes

Suffixes are perhaps the most complex and critical part of bearing designations, as they define specific features that can significantly affect bearing performance and compatibility. Suffixes are crucial for determining the suitability of a bearing for a specific application.

Seals and Shields

Bearing seals and shields are among the most commonly specified suffixes, as they determine the bearing’s protection against contaminants and retention of lubricant:

- Z: Single shield (metal shield on one side)

- ZZ: Double shields (metal shields on both sides)

- RS: Single rubber seal (contact seal on one side)

- 2RS: Double rubber seals (contact seals on both sides)

- RZ: Single rubber seal with reduced contact

- 2RZ: Double rubber seals with reduced contact

Cage Materials

The cage (or separator) holds the rolling elements in proper position and can significantly affect bearing performance:

- J: Steel cage (pressed steel)

- M: Brass cage (machined brass)

- TN: Polyamide cage (glass fiber reinforced)

- TV: Polyamide cage with special design

- HA: High-temperature resistant cage

Internal Clearance

Internal clearance affects bearing performance, especially in applications with temperature variations:

- C2: Less than normal radial internal clearance

- C0: Normal radial internal clearance (standard)

- C3: Greater than normal radial internal clearance

- C4: Much greater than normal radial internal clearance

- C5: Very large radial internal clearance

Preload and Precision

Some suffixes indicate precision levels or preload conditions:

- P5: Precision grade 5 (high precision)

- P6: Precision grade 6 (normal precision)

- DB: Back-to-back mounting arrangement

- DF: Face-to-face mounting arrangement

- DT: Tandem mounting arrangement

Example Breakdown

To illustrate how all these elements work together, let’s break down a complete bearing designation:

Example: S 6205 2RS C3

Breaking down the bearing designation “S 6205 2RS C3”:

- S: Prefix indicating stainless steel construction

- 6: Bearing type – Deep groove ball bearing

- 2: Dimension series – Medium series

- 05: Bore size code = 05 × 5 = 25 mm bore diameter

- 2RS: Suffix indicating double rubber seals (contact seals on both sides)

- C3: Suffix indicating greater than normal radial internal clearance

This bearing is therefore a stainless steel deep groove ball bearing with:

- 25 mm bore diameter

- Medium series dimensions

- Double rubber seals for contamination protection

- Increased internal clearance for high-temperature applications

Such a bearing would be suitable for applications requiring corrosion resistance, contamination protection, and operation at elevated temperatures where thermal expansion might affect internal clearance.

Example: 7206 BEP

Another example: “7206 BEP”

- 7: Bearing type – Angular contact ball bearing

- 2: Dimension series – Medium series

- 06: Bore size code = 06 × 5 = 30 mm bore diameter

- BEP: Suffix indicating brass cage with special design

This bearing is an angular contact ball bearing with a 30 mm bore diameter, medium series dimensions, and a brass cage designed for specific performance characteristics.

Manufacturer Variations

While the basic principles of bearing numbering are consistent across manufacturers, there are variations in specific designations and suffix meanings. Understanding these differences is crucial when working with bearings from different manufacturers.

Major Bearing Manufacturers

The world’s leading bearing manufacturers each have their own numbering systems and suffix conventions:

- SKF: Swedish manufacturer, one of the world’s largest bearing companies

- NSK: Japanese manufacturer with strong global presence

- NTN: Japanese manufacturer specializing in precision bearings

- FAG: German manufacturer, part of Schaeffler Group

- INA: German manufacturer, also part of Schaeffler Group

- Timken: American manufacturer specializing in tapered roller bearings

- KOYO: Japanese manufacturer, part of JTEKT Corporation

Common Variations

Some common variations between manufacturers include:

- Suffix Meanings: The same suffix may have different meanings between manufacturers

- Order of Suffixes: The sequence of suffixes may vary

- Special Designations: Some manufacturers use unique designations for proprietary features

- Dimension Standards: Metric vs. inch series bearings may use different numbering systems

Cross-Referencing

Cross-referencing bearings between manufacturers is often necessary for replacement purposes:

- Dimensional Interchangeability: Bearings with the same dimensions may have different part numbers

- Performance Equivalence: Performance characteristics may differ even with similar dimensions

- Special Features: Proprietary features may not have direct equivalents

Practical Applications

Understanding bearing numbers has numerous practical applications in engineering maintenance and machinery operation.

Maintenance and Replacement

Accurate bearing number interpretation is critical for:

- Preventive Maintenance: Identifying bearings that need replacement before failure

- Emergency Repairs: Quickly sourcing correct replacement bearings

- Inventory Management: Maintaining appropriate stock levels of critical bearings

- Cost Control: Avoiding expensive mistakes from incorrect replacements

Equipment Design and Selection

Engineers use bearing numbers during the design process to:

- Select Appropriate Bearings: Choose bearings that meet load, speed, and environmental requirements

- Ensure Compatibility: Verify that bearings will properly fit shafts and housings

- Optimize Performance: Specify features like seals, cages, and clearances for specific applications

- Plan for Maintenance: Select bearings that are readily available and easy to service

Troubleshooting and Failure Analysis

Understanding bearing numbers aids in:

- Failure Investigation: Determining if incorrect bearings were installed

- Root Cause Analysis: Identifying whether bearing selection contributed to equipment problems

- Preventive Measures: Specifying better-suited bearings for future installations

Common Mistakes and How to Avoid Them

Several common mistakes occur when interpreting bearing numbers, which can lead to costly errors in bearing selection and application.

Bore Size Calculation Errors

The most common mistake involves bore size calculations:

- Ignoring Exceptions: Forgetting that codes 00, 01, 02, and 03 have special meanings

- Metric vs. Inch: Confusing metric bearings with inch series bearings

- Units: Mixing millimeters and inches in calculations

Suffix Misinterpretation

Misunderstanding suffix meanings can lead to serious application problems:

- Seal/Shield Confusion: Installing sealed bearings where shields are required or vice versa

- Clearance Issues: Using standard clearance bearings in high-temperature applications

- Cage Material Errors: Installing bearings with incompatible cage materials for specific environments

Manufacturer-Specific Confusion

Assuming all manufacturers use identical numbering systems:

- Suffix Differences: The same suffix may mean different things for different manufacturers

- Designation Order: The order of prefixes and suffixes may vary

- Proprietary Features: Some features may be manufacturer-specific

Resources and Reference Materials

Numerous resources are available to help engineers and technicians understand bearing numbers and make proper selections.

Manufacturer Catalogs and Websites

The most reliable sources for bearing information:

- SKF Handbook: Comprehensive reference for SKF bearings and numbering system

- NSK Catalogs: Detailed information on NSK bearing designations

- NTN Technical Literature: Extensive documentation on NTN bearing specifications

- FAG/INA Documentation: Detailed information on Schaeffler Group bearings

Industry Standards

Standardized references that provide universal guidance:

- ISO Standards: International standards for bearing dimensions and designations

- ABEC Standards: Annular Bearing Engineers Committee standards for precision bearings

- DIN Standards: German industrial standards for bearing specifications

Online Tools and Software

Digital resources that simplify bearing selection:

- Bearing Selection Software: Interactive tools from major manufacturers

- Online Catalogs: Searchable databases of bearing specifications

- Mobile Apps: Smartphone applications for bearing identification

- Cross-Reference Tools: Software that matches bearings between manufacturers

Sample Problems and Practice

Let’s work through some examples to reinforce understanding of bearing numbers.

Problem 1: Basic Bearing Identification

Identify the type, bore diameter, and basic characteristics of bearing 6308.

Solution:

- 6: Deep groove ball bearing

- 3: Dimension series – Medium heavy series

- 08: Bore size code = 08 × 5 = 40 mm bore diameter

This is a deep groove ball bearing with a 40 mm bore diameter and medium heavy series dimensions.

Problem 2: Suffix Interpretation

Explain the complete specification of bearing 7207 BEP.

Solution:

- 7: Angular contact ball bearing

- 2: Dimension series – Medium series

- 07: Bore size code = 07 × 5 = 35 mm bore diameter

- BEP: Brass cage with special design

This is an angular contact ball bearing with a 35 mm bore diameter, medium series dimensions, and a brass cage designed for specific performance characteristics.

Problem 3: Complex Designation

Interpret the bearing designation S 6004 ZZ C3.

Solution:

- S: Stainless steel construction

- 6: Deep groove ball bearing

- 0: Dimension series – Extra light series

- 04: Bore size code = 04 × 5 = 20 mm bore diameter

- ZZ: Double shields (metal shields on both sides)

- C3: Greater than normal radial internal clearance

This is a stainless steel deep groove ball bearing with 20 mm bore diameter, extra light series dimensions, double metal shields, and increased internal clearance for high-temperature operation.

Conclusion

Understanding bearing numbers is a fundamental skill for engineers, maintenance personnel, and procurement specialists working with mechanical systems. The standardized numbering system provides a concise yet comprehensive method for specifying bearing characteristics, dimensions, and special features.

The basic bearing designation (typically four digits) encodes the most critical information: bearing type, dimension series, and bore diameter. Mastering the bore size calculation, with its important exceptions for codes 00, 01, 02, and 03, is essential for proper bearing selection.

Prefixes and suffixes add layers of information about special features such as materials, seals, cages, and internal clearances. These additions can significantly affect bearing performance and suitability for specific applications, making their proper interpretation crucial for successful bearing application.

The examples and sample problems demonstrate how to systematically decode bearing numbers, revealing the wealth of information contained in these seemingly simple designations. This knowledge enables quick and accurate bearing identification, selection, and replacement.

While the basic principles are consistent across manufacturers, variations in specific designations and suffix meanings require careful attention when working with bearings from different sources. Utilizing manufacturer catalogs and reference materials is essential for accurate interpretation.

Common mistakes in bearing number interpretation, particularly regarding bore size calculations and suffix meanings, can lead to costly errors and equipment failures. Understanding these potential pitfalls and how to avoid them is as important as knowing the correct interpretation methods.

The practical applications of bearing number knowledge span the entire lifecycle of mechanical equipment, from initial design and procurement through maintenance and replacement. Proper bearing selection based on accurate number interpretation contributes directly to equipment reliability, operational efficiency, and cost control.

As mechanical systems become more complex and operating conditions more demanding, the importance of precise bearing specification and selection continues to grow. Modern bearing technology offers increasingly specialized solutions, making detailed understanding of bearing numbers even more critical.

For students and practitioners of mechanical engineering and maintenance, mastering bearing numbers represents an investment in professional competence that pays dividends throughout their careers. The ability to quickly and accurately interpret bearing designations enhances problem-solving capabilities and decision-making confidence in bearing-related applications.

In conclusion, bearing numbers are far more than simple identification codes—they are a sophisticated language that enables precise communication about some of the most critical components in mechanical systems. Mastery of this language is essential for anyone involved in the design, maintenance, or operation of rotating machinery.