Stress in Thin Spherical Shell – Engineering Made Easy

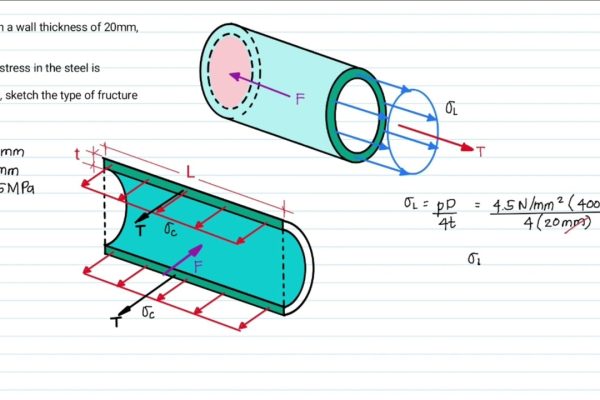

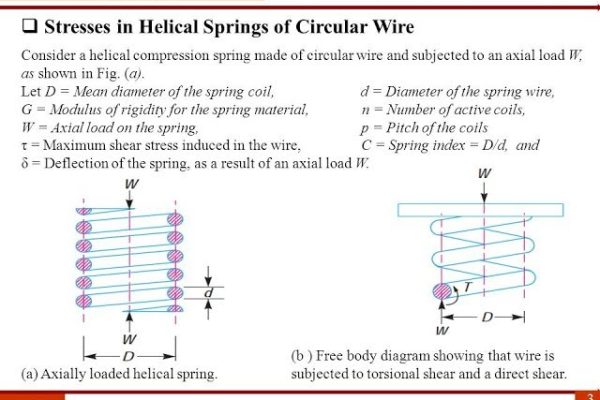

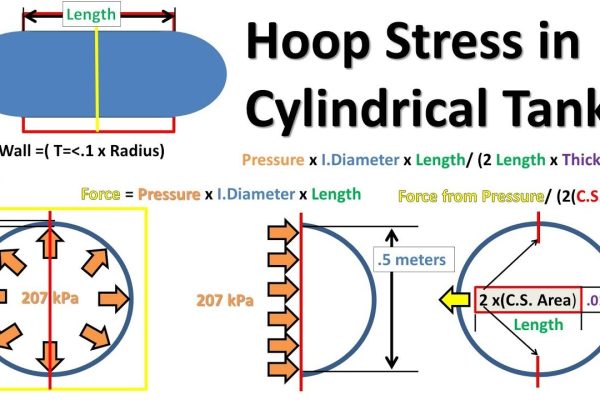

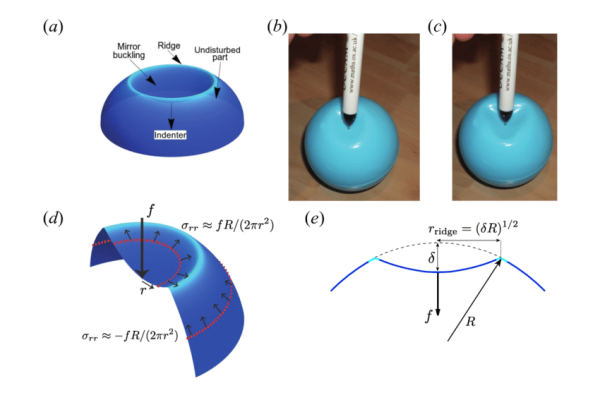

In the field of engineering mechanics and structural analysis, understanding the stress distribution in thin-walled pressure vessels is fundamental to the safe and efficient design of numerous engineering components. Among the various geometries of pressure vessels, spherical shells represent one of the most efficient configurations for containing internal pressure due to their uniform stress distribution…